Low Payload Robots

When many think of industrial robots they may picture large, bulky machines designed for heavy lifting. While heavy payload robots are common, low payload robots are just as popular. Robot payload is the amount of weight a robot arm is capable of lifting. This not only includes parts manipulated by the robot, but also the EOAT integrated with it. Payload capacity is one of the most important factors that should be considered when selecting an industrial robot.

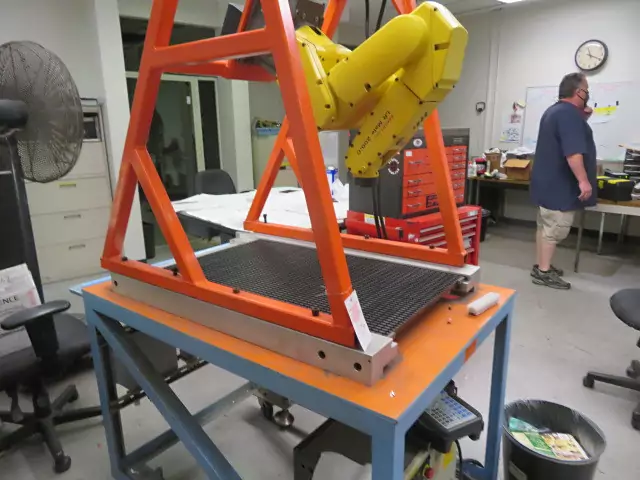

In general, a low payload robot qualifies as any model with a maximum payload capacity of 20 kg or less. Low payload robots usually feature a compact profile, slim arm design, and a lighter robot mass. These features make them more adaptable to most manufacturing facilities with the capability of multiple mounting options such as overhead, tabletop, floor, or wall. The FANUC Lr Mate 200ic can be mounted pretty much any way the user requires.

Low payload robots can consist of delta, SCARA, articulated, and collaborative robot types. Delta robots feature a unique spider-like design and ultra-light payloads with some starting at as little as 0.5 kg. FANUC’s delta robot family features the well-known M-1ia. SCARA robots also feature a unique configuration designed for lateral movements. SCARA robots average a payload capacity of 6 kg.

Applications for Low Payload Robots

There are a number of applications that can be automated with low payload robots. Just because they are limited as to how much weight they can handle does not mean they are limited by the tasks they can automate. Low payload robots can complete many applications including robotic assembly, welding automation,and robotic pick and place. In fact most arc welding robots have a payload of 20KG or less. Both the popular FANUC Arcmate 120ic and the Motoman MA1400 have low payloads and are perfect for robotic TIG and automated plasma welding.Many low payload robots have been deployed for manufacturing delicate products. The electronics industry has become a major user of industrial robots, especially as electronic components have become smaller and more fragile. The FANUC Lr Mate 200id is ideal for handling intricate assemblies with its control and precision. Other industries implementing low payload robots include the pharmaceutical, medical, and food industries.