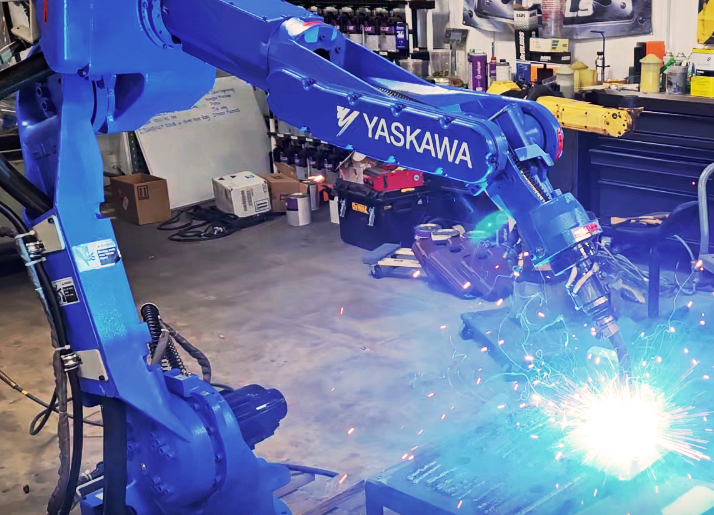

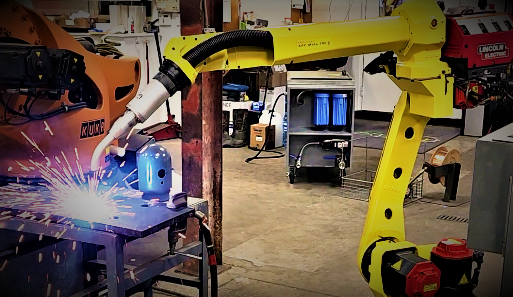

Robotic or robot arc welding is the process in which an industrial robot performs an automated weld on a item that was likely prepared by an human. Arc welding is the process of using electricity to merge metal with metal. A robotic welding power supply is used to create an electric arc between an electrode and the base material. Welding automation increases safety and productivity. Subcategories based on different processes and power supplies include:

- Flux-Cored Arc Welding

- Gas Metal Arc Welding

- Gas Tungsten Arc Welding

- Metal Active Gas Welding

- Metal Inert Gas Welding

- Plasma Arc Welding

- Shielded Metal Arc Welding

- Tungsten Inert Gas Welding

Smaller robots such as a FANUC Arc Mate 100ic with a FANUC R30ia controller are typically integrated to a multi-process welder like a Lincoln Power Wave i400 in order to perform the 2 more common types of arc welding, MIG and TIG. The FANUC robot is then put into a robotic workcell or set up with a stationary welding table to perform the desired operation. Larger robots such as a FANUC M-710ic/50 can be used on applications that require a longer reach. Generally a welding robot does not require a very heavy payload, therefore it is uncommon to utilize a larger robot like a FANUC R-2000b for this application. As with robotic welding in general, various advantages of robotic welding exist, including:

- Increased safety to workers – Integrating a Motoman MA1400 robot with Motoman DX100 controller with a Miller Auto-Axcess 450 will take the welding torch out of the hands of a worker, moving that worker to the much safer job of loading parts and operating the robot. Many robotic welding operations utilize the use of a welding cell to perform an application. Automating the arc welding process will increase the safety of the workplace.

- Increased accuracy – Arc welding robots such as the FANUC Arc mate 100ic with a FANUC R-30ia controller are more precise than humans. They perform the same weld within millimeters each time. Even the most accurate human welder cannot match the accuracy of an industrial robot. Integrating a robotic arc welder will result in less mistakes and increased productivity.

- Increased consistency – When an robotic system is programed to perform a weld, it remembers the programming and follows the exact pattern on every weld. With the repeatability of the FANUC 120ib the weld will appear the same every single time.

- Decreased human error – As previously noted even the most skilled welders make mistakes from time to time. Welding robots such as the FANUC Arc mate 120ic with FANUC R30ia controller can perform thousands of welds without error. This increases productivity and decreases waste.

- Return on investment - Once a used welding robot is integrated into an application, it will work for a long period of time without issues. Purchasing a Used Motoman welding robot such as an used Motoman EA1900N with a Miller Axcess 450 welder can return the entire investment in under 2 years.

Contact us by email mm@robotsdoneright.com or phone (440) 724-6568 today to discuss buying or selling a arc welding robot.