What is a Robotic Manipulator?

A robotic manipulator arm is a reprogrammable and multifunctional mechanical device responsible for moving materials, parts, objects, or tools through programmed motions in order to perform various tasks. These mechanical devices are composed of a series of jointed segments that form an arm-like manipulator. A robotic manipulator is capable of moving or handling objects automatically depending upon its given number of degrees of freedom. Those degrees of freedom are also known as axes. Each axis of a robotic manipulator correlates to the number of motors within the robot. Robotic manipulators can range from two axes to ten or more. Most robots used in industrial settings have between four to six axes. Six-axis robotic manipulators are the most common since their range of motion is similar to the human arm. This provides the flexibility needed to automate many industrial processes with robots.

The general construction of a robotic manipulator consists of rigid links that are connected by joints. One end of the manipulator is fixed to a base while the other end is free and used for performing different robotic applications. The structure of the robotic manipulator will determine the reach of its end-effector and its work envelope.

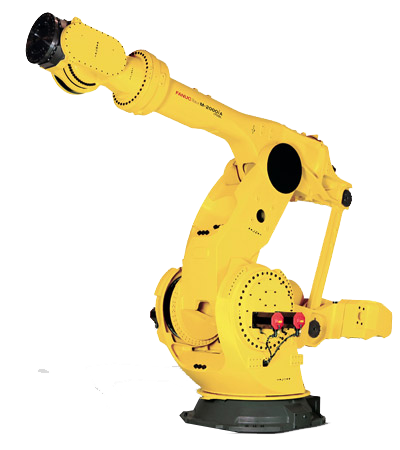

Robotic manipulators are typically divided into two parts; the arm/body and the wrist. The arm and body of the manipulator control the movement of objects within the robot’s work envelope. For instance, when a FANUC M710ic/50 moves a part onto a conveyor. While the wrist controls the movement of the end-effector, allowing the manipulator to carry out the task it has been programmed for, such as the FANUC M-20ia picking up a part with its gripper.

Types

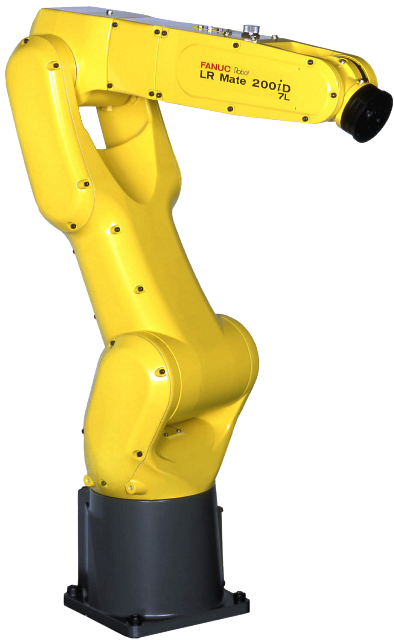

There are several types of robotic manipulators. These types vary based upon the combination of joints and include cartesian, cylindrical, polar, articulated, SCARA, and delta configurations. Articulated manipulators are the most widely used and recognized type in manufacturing. They feature a revolute shoulder joint that allows for rotation. The FANUC Lr Mate 200id and the ABB IRB 2600 are two examples of articulated robots. Cartesian manipulators consist of prismatic or sliding joints, providing a rectangular work envelope. Cylindrical and polar manipulators both consist of revolute joints. The work envelope of cylindrical robots is cylindrical, while polar robots operate within a spherical envelope. SCARA and delta manipulators both utilize parallel joint configurations.Applications

All robotic manipulators include a controller and teach pendant. A teach pendant is used to program the robotic manipulator while the controller functions as the “brain,” allowing the robot to interpret and carry out the desired operations of the program. How the manipulator operates depends upon its payload capacity, speed, and repeatability.Robot manipulators are capable of automating a number of different types of applications. Some of the most common include automated welding, robotic assembly, material removal, material handling, painting, robotic palletizing, and automated pick and place. Advancements in technology has greatly improved the accuracy and precision of robotic manipulators, allowing for the automation of new applications such as robotic 3D printing. As manipulators become more sophisticated so does the scope of robotic applications. Manufacturing processes become more efficient, reliable, and productive with industrial robot automation.