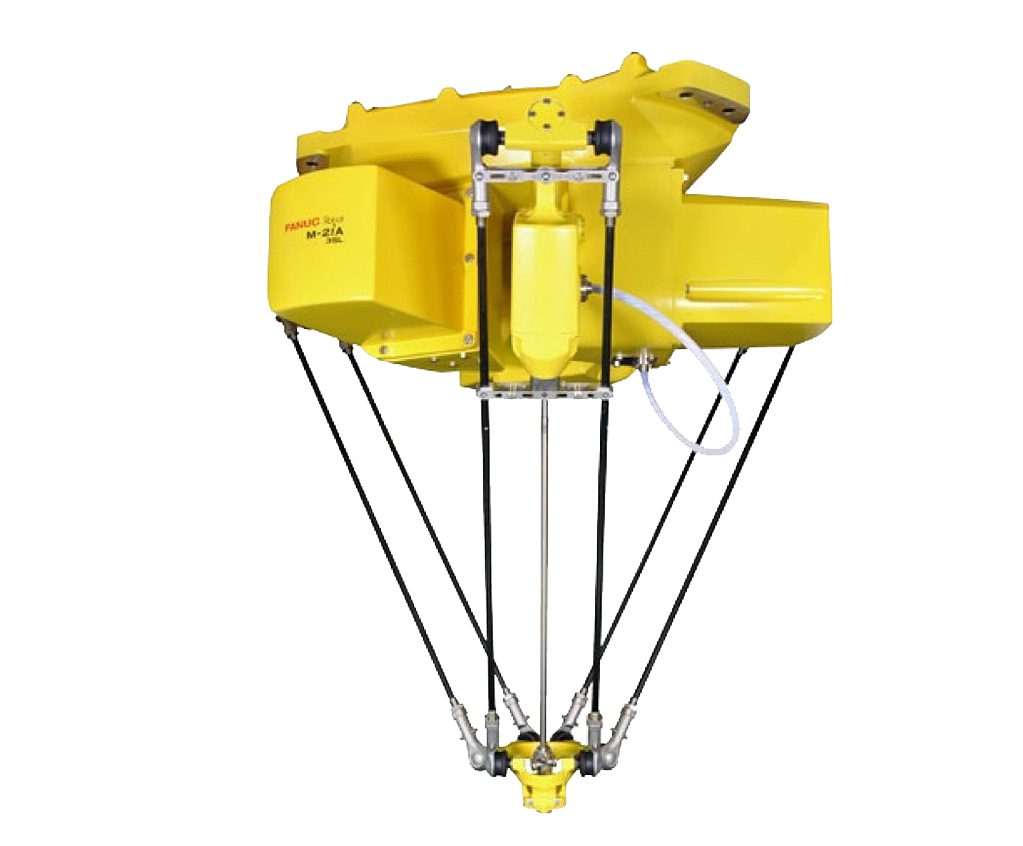

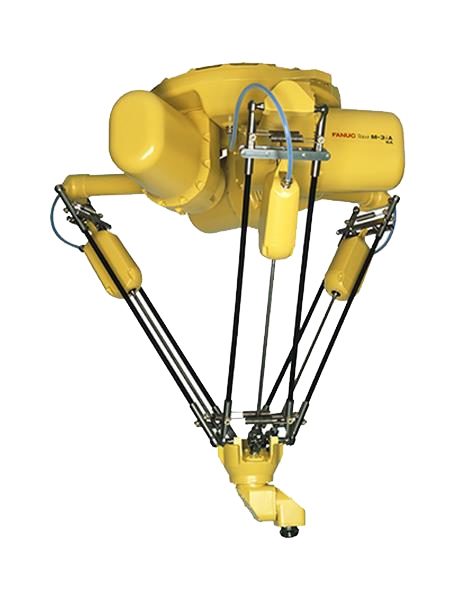

Delta robots were originally created in the 1980s but did not start to gain notice in the manufacturing world until about ten years ago. Now delta robots can be commonly found along many assembly lines across numerous industries. These robots are also known as parallel-link robots due to their parallelogram arm design. Delta robots typically have three to four carbon-fiber, lightweight arms that extend downward from the main robot body. Because of this design they are often referred to as spider robots with the spider-like resemblance of their arms.

Delta robot arms are jointed in the middle, causing them to bend inward and connect to a small tooling plate. This small tooling plate is where the end-effector can be attached. Each arm is connected to a motor that is located within the main robot body. The motors coordinate movements of the arms in up and down motions, which pushes their joints inward and outward. These joint movements cause the tooling plate to move across X, Y, and Z axes, creating a cylindrical work envelope. One of the robot arms is used to control the end-effector by extending from the center of the robot body.

Delta robots are known for their high speed and high accelerations. Their design is what makes them speedier than other types of industrial robots. Most industrial robots have motors located in the robot arm, making them conducive for heavier payload applications. However, having the motors in the robot arm adds additional weight and prohibits fast speeds. With delta robots all motors are located in the main body above the work area. This keeps all the main weight of the robot stationary. All movement comes from the extremely light robot arms, allowing for low inertia for incredibly fast operating speeds and accelerations.

Applications For Spider Robots

Delta robots are ideal for assembly, dispensing, pick and place, material handling, part transfer, and packaging robotic applications. Parts handled by delta robots should be lightweight and consist of simple geometries, since these robots operate at fast speeds. Heavier parts or complex parts are not conducive to the speeds and accelerations of delta robots.Many of these robots have been deployed in the food, electronic, medical, and pharmaceutical industries for lightweight assembly processes. These robots have been proven to drastically increase productivity and reduce cycle times. Some delta robots are capable of picking up to 300 parts per minute for dramatically high throughput rates. Delta robots can also be integrated with additional robotic technology such as force sensors and vision. These systems enhance and fine-tune the precision and accuracy of spider robots, allowing for more complex applications to be automated.