Robots Done Right |

Used Robot Sales |

Packaging Robots

Packaging is one of the most crucial steps of a manufacturing process as without it, products would never reach consumers. It is a process that requires precision and speed in order for operations to remain cost-effective and for companies to maximize sales. This is why manufacturers are automating their packaging processes with robotics. Packaging robots can be integrated with EOAT (end of arm tooling) to meet a variety of packaging application needs. They are designed to mimic human movements to lift parts or products from assembly lines and carefully place them into packages with precision. Packaging robots are becoming a popular addition for industries such as food, pharmaceutical, electronics, and cosmetics among many others.

Packaging is one of the most crucial steps of a manufacturing process as without it, products would never reach consumers. It is a process that requires precision and speed in order for operations to remain cost-effective and for companies to maximize sales. This is why manufacturers are automating their packaging processes with robotics. Packaging robots can be integrated with EOAT (end of arm tooling) to meet a variety of packaging application needs. They are designed to mimic human movements to lift parts or products from assembly lines and carefully place them into packages with precision. Packaging robots are becoming a popular addition for industries such as food, pharmaceutical, electronics, and cosmetics among many others.

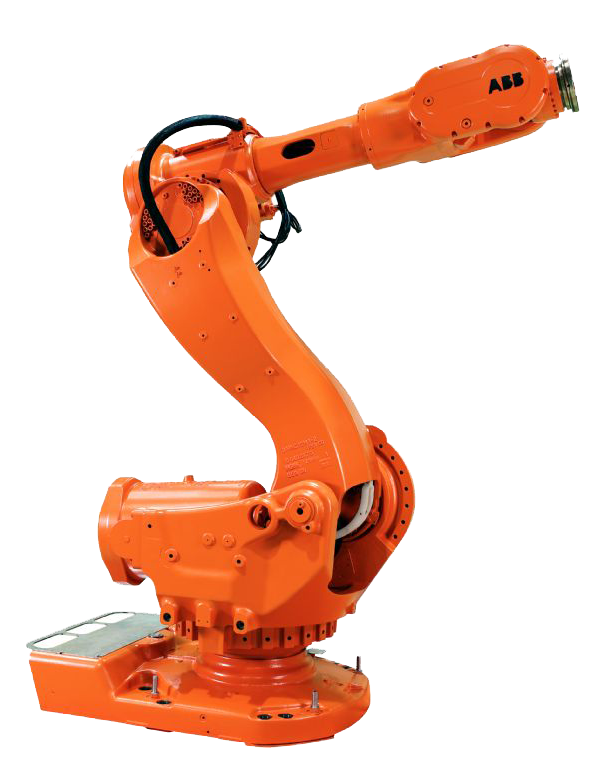

A variety of robot types can be used to automate packaging applications, some of the most common ones include SCARA and articulated arm robots. SCARA robots, such as the FANUC SR-3ia, are ideal for sorting and packaging at high speeds. While articulated ABB robots like the ABB IRB 6640-205/2.75 are great for the packaging of large products.

The flexibility of packaging robots gives manufacturers more freedom within their productions. These robots can handle a number of environments including those that would to too harsh for human workers. High levels of dust or warm temperatures do not hinder the work of a robot and manufacturers eliminate costs associated with work related injuries. Adding to their flexibility is their small footprint and ability to be mounted from several positions including above the assembly line. This frees up floor space which will be needed due to their high productivity rate. Manufacturers also do not have to worry about retraining or reconfiguring production lines if products change. Packaging robots can easily be reprogrammed and redeployed to meet changing trends further adding to their versatility.

The repetitive nature of packaging applications makes FANUC robots like the FANUC M-710ic/70 an ideal candidate to complete them. The repetitiveness that is viewed as ideal for robots can be viewed as mundane and unfulfilling to human workers. Workers may become burnt out by the laborious nature of packaging which could lead to high turnover for companies or difficulty finding employees to fill these jobs. With robots these headaches become obsolete and labor costs are reduced.

Robotic packaging is a cost-effective solution for manufacturers looking to streamline their operations and retain an edge over their competitors.

Contact us by email mm@robotsdoneright.com or phone (440) 724-6568 today to discuss buying or selling a packaging robot.