Automating the Medical & Pharmaceutical Industries with FANUC Robots

Advances in robotic technology has led to the adoption of robotics outside of traditional industrial settings. Two industries welcoming robotic automation are the medical and pharmaceutical industries and they are doing so with FANUC robots. FANUC robots are helping with manufacturing medical devices, constructing medical test kits, and packaging medications. The wide range of robot models offered by FANUC have payload capabilities ranging from 0.5 to 2,300kg to handle tasks as delicate as bottling pills to powerful ones such as palletizing boxes of medical devices. FANUC robots can be found performing a number of applications in these industries, including: assembly, dispensing, machine tending, material handling, and packaging.

Benefits of Automating with FANUC Robotics

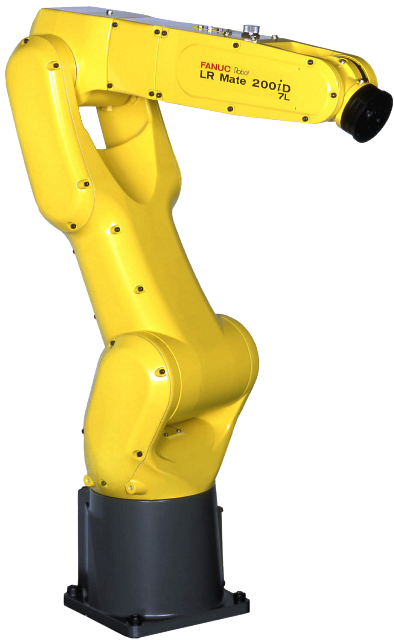

The incorporation of FANUC robotics in the medical and pharmaceutical industries is helping to prevent product contamination, increase production flexibility, increase consistency, and provide greater precision:- Contamination - You may be wondering how FANUC robots can prevent contamination or even work in these industries with their stringent regulatory standards, especially since industrial robots tend to have the stigma of being greasy or dirty. With FANUC’s line of cleanroom robots, such as the FANUC Lr Mate 200ic, they actually meet the extremely high requirements of cleanroom environments often used for medical and pharmaceutical industries. They have special coatings and non-gassing lubricants to prevent any contaminants spreading from the robot to the production line. These robots are integrated with cameras, vision systems, and sensors to handle sensitive materials with delicacy to prevent compromising product quality. They eliminate the need for human handling which always carries the risk of possible product contamination.

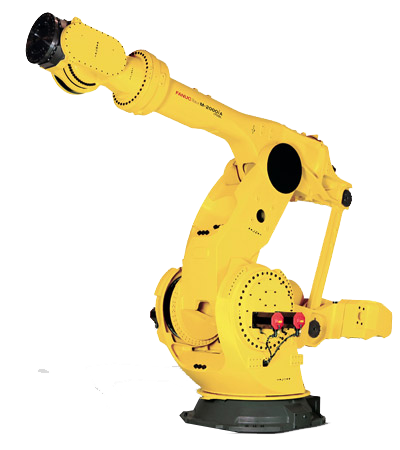

- Flexibility - Before robots manufacturers in the medical device industry relied on hard machining that greatly lacked any sort of flexibility with machines only being capable of performing one specific task. This slowed production and made for higher costs. FANUC robots increase flexibility since they can be programmed to handle a variety of applications as mentioned above. Robots like the FANUC M-20ia can be equipped with flexible tool changers to quickly adapt to the assembly of different products with no interruption to operations. It can go from a pick and place gripper to an adhesive dispenser, streamlining the manufacturing process and further reducing cycle time. Vision and force control systems provide FANUC robots the capability to adapt on-demand to changes in parts while in operation. If there is a change in the product line the robot can simply be reprogrammed and redeployed, so manufacturers are never at a loss when investing in FANUC robots.

- Consistency - In the medical and pharmaceutical industries consistency is key to ensure products meet regulations and to protect product safety. The high repeatability of FANUC robots like the FANUC M-10ia eliminates any deviation from each product produced. These robots are programmed to follow application parameters with accuracy, preventing errors that could compromise product integrity.

- Precision - Medical devices often involve the manufacturing of small, intricate parts. FANUC robots such as the FANUC M-6ib are capable of handling these parts with precision to ensure they are carefully and correctly assembled without damage. Vision and force control further guide FANUC robots dynamically perform complex tasks such as inserting a small pin into a curved tube.