Automating with Industrial Robots

Automating with industrial robots may seem intimidating to many who are new to robotics. The reality is that in today’s highly competitive and demanding global market, manufacturers cannot afford to have this fear anymore. In fact, industrial robots are becoming the standard for many manufacturing processes with robotic installation bases increasing each year. Industrial robots have come a long way since their inception in the 1960s with technological advances making them more autonomous and easier to program, helping those new to robotic automation quickly lose their trepidation.

Top Reasons for Industrial Robot Automation

A company can economically automate an arc welding application with a FANUC Arc mate 100ic or an assembly application using a ABB IRB 2600-20. Some of the most common reasons include:- To Stay Competitive - Technology has benefited manufacturers tremendously with expanding markets to the global scale. With that global expansion also comes increased competition from across the world. As the number of consumers increases, demand for products also increases, which can be hard for businesses to keep up with. Industrial robots help manufacturers solve their productivity issues along with helping them stay competitive in global markets. The ABB IRB 7600 can work around the clock with faster cycle times than humans, increasing productivity levels and saving time which can be costly. With shorter production times and more products readily available, manufacturers can offer competitive prices that will drive more consumers to them.

- To Improve Quality - Not only do today’s manufacturers need to meet higher product demands, but also higher quality demands. It can be challenging to produce more products without sacrificing quality. This is where industrial robots excel, and can bridge the gap between productivity and quality. Robots are programmed for precision that is repeatable with every workpiece. Products manufactured with industrial robots turn out uniform without mistakes or defects, improving quality.

- To Reduce Costs - Reducing production costs is another popular reason for robotic automation. Many times, high costs are associated with material waste or scrapped products that were damaged during manufacture. Industrial robots eliminate these issues with their high level of accuracy. The programmable precision of robots ensures mistakes are not made that lead to material waste. Costs can be further reduced since less manhours are needed as robots can operate twenty-four hours a day autonomously.

What Applications can be Automated with Robots?

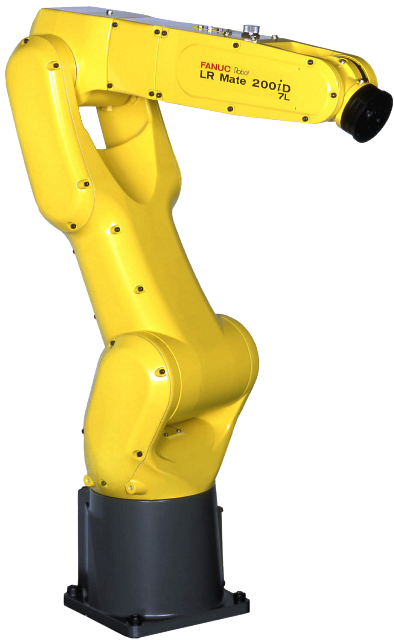

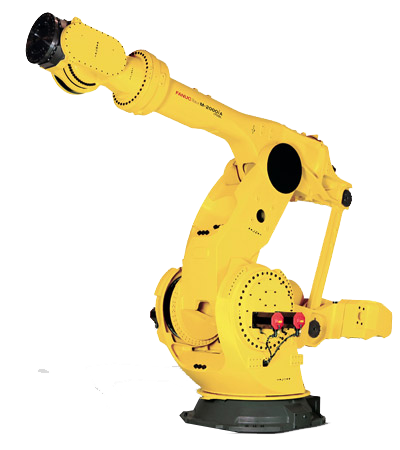

In general, industrial robots are best for performing applications that are repetitive, high-volume, and precise. Improvements in robotic technology has led to numerous manufacturing applications to become automated with robots, even ones that were once considered too complex and advanced. Common robotic applications include: arc welding, spot welding, assembly, material handling, material removal, pick and place, packaging, palletizing, painting, machine loading, machine tending and part transfer.The FANUC M-20ia is capable of performing arc welding and material removal. While the Motoman 50-20 can complete plasma welding or plasma cutting applications. The FANUC R-2000ib is capable of performing both material handling and spot welding applications. Having a robot capable of multiple application types is advantageous since they can perform multiple steps of a production cycle or be redeployed should production needs change in the future.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.