Robots Done Right |

Used Robot Sales |

Spot Welding Robots

Spot welding, also known as spot resistance welding, is one of the most common robotic welding applications and is frequently used in the automotive industry. Spot welding applications are fully automated by integrating industrial robots, such as the ABB IRB 6640-235/2.55, with welding guns in order to join metals together through heat produced from resistance to an electrical current. Copper alloy electrodes are used to concentrate the weld current to a small area or spot on the workpiece. Pressure exerted by the electrodes holds the metals together while the concentrated weld current is forced through the spot, melting the metals and creating the weld.

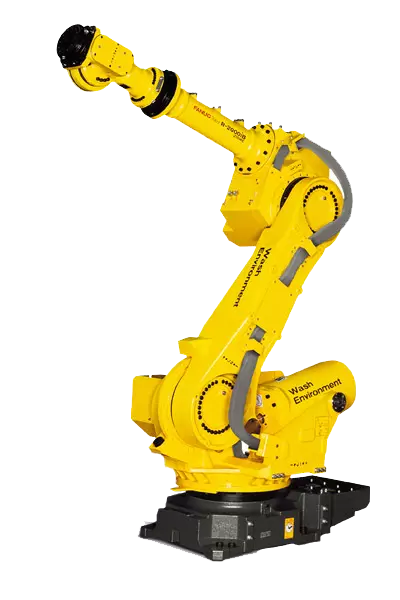

Spot welding is an attractive welding application to manufacturers due to the delivery of high amounts of energy (heat) to a spot within a short amount of time, about 10-100 milliseconds. The concentration of heat to a particular spot in a short timeframe prevents excessive heating of the remainder of the metal, preventing any distortion. This makes spot welding robots ideal for welding thin metals, for example, sheet metal to form a car frame in the automotive industry. The FANUC M-900ia/350 has a payload of 350 KG allowing it to handle heavy spot welding end of arm tooling

Spot welding robots also increase product quality because they can control the level of energy (heat) delivered to the weld area. The ability to control the energy level ensures the correct amount is applied every time producing reliable, long-lasting welds. If too little heat is applied, it will result in a poor weld. If too much heat is applied, the metals will melt too much, and a hole will result instead of a weld. The heat control provided by spot welding robots like the ABB IRB 6640-235/2.55, also prevents the waste of materials and helps manufacturers save on material costs.

Another advantage of robotic spot welding for manufacturers is improved worker safety. Not only can spot welding be taxing due to the repeated operation of a heavy weld gun, but it is also quite dangerous. Workers risk being exposed to hot molten metal and sparks, both of which can lead to severe burns. Other hazards include electric shock from the welding power supply, high noise levels, and bruising caused by excessive force when coming too close to the electrodes. These potential risks can cause production delays and high worker injury claims for manufacturers. FANUC R2000 robots are not subject to the risks of spot welding applications and keep operations running smoothly regardless of the hazards. Contact us by email mm@robotsdoneright.com or phone (440) 724-6568 today to discuss buying or selling a spot welding robot.