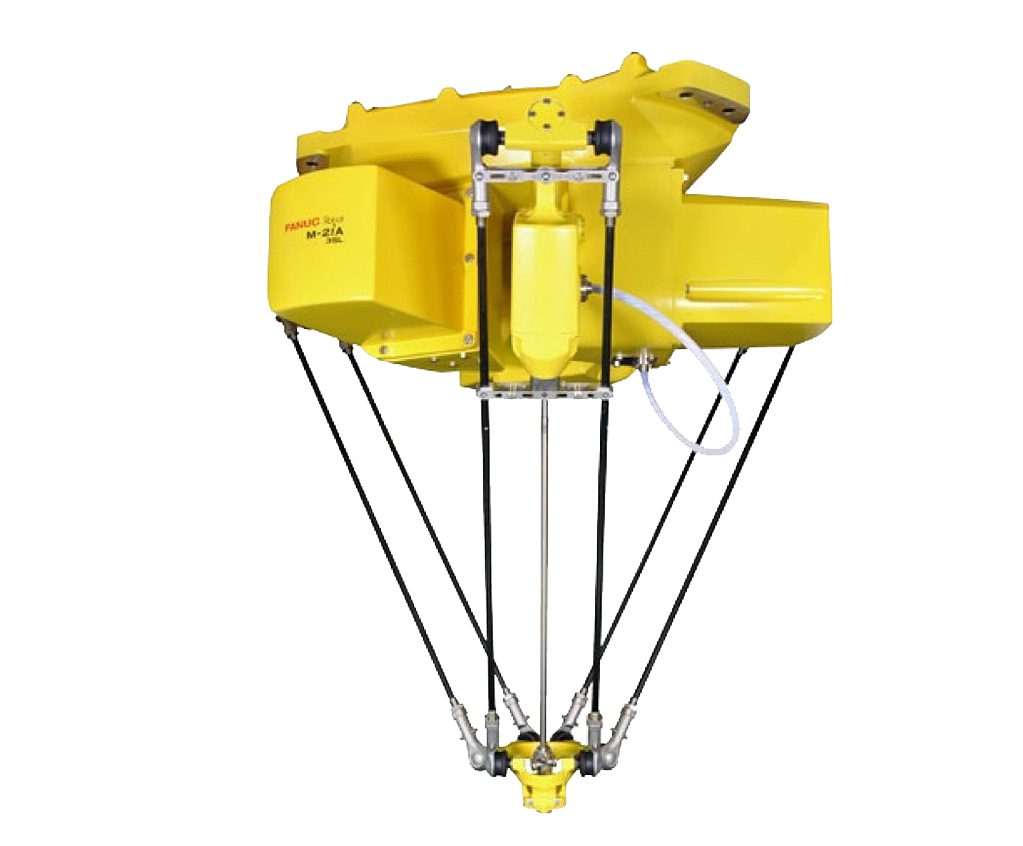

FANUC M-2ia Overview

The FANUC M-2iA is a unique Delta style robot featuring a 6-axis structure. The M-2iA is designed to handle parts of 6 kg or less for picking, assembly, and packaging applications. In addition, its reach of up to 1130 mm allows for an expanded work envelope with a smaller robot footprint. It can be mounted overhead for further space savings along production lines.

Robots In Stock

Additional variations of this robot:

M-2ia/3A

The FANUC M-2iA/3A is a unique Delta style robot featuring a 6-axis structure. The M-2iA-3A is designed to handle parts of 3 kg or less for picking, assembly, and packaging applications. In addition, its reach of up to 800 mm allows for an expanded work envelope with a smaller robot footprint. It can be mounted overhead for further space savings along production lines.The parallel link arm of the m-2ia-3a features an additional 3 axes at its wrist for best in class articulation. Its articulated wrist allows for full rotation of workpieces at fast speeds for enhanced operation flexibility and reduced cycle times.

The m/2ia/3a can be configured with additional protection options to allow for operation in special work environments. An IP69K option is available to protect the FANUC M-2iA/3-A from water and severe dust. The IP69K option also protects against high-pressure cleaning, making the M-2iA-3/A extremely durable for a Delta robot. While a food safe option is also available to meet sanitary standards for the safe handling of food and beverages. The food safe package coats the m/2ia/3a with a high-quality surface treatment and replaces traditional robot lubricant with food grade grease.

The FANUC M-2iA-3A is compatible with the R-30iB controller and its variants. The R-30iB controller provides intelligent programming for users allowing for easy integration of the FANUC m-2ia/3/a.

M-2ia/3AL

The FANUC M-2iA/3AL robot is a high-speed automation solution for pick and place, assembly, and packaging applications. This 6-axis Delta robot features an expanded work envelope with a reach of 1130 mm. The M-2iA-3AL is the long reach variant of the FANUC M-2iA/3A, but still provides the same 3 kg payload capacity for light part handling.Despite having a bigger work scope, the m-2ia/3-al can still operate with the same fast speed and agility as the other M-2iA series robots. Its parallel link arm has a 3-axis wrist, providing the M2iA3AL the freedom to fully rotate workpieces and tooling required for manufacturing. The FANUC m-2ia-3a/l is known as being best in class for full articulation due to its wrist design.

The m-2ia/3al is one of the most durable Delta robots available with an IP rating of 67 being standard. This means it is able to withstand water and dust intrusion, making it suitable for harsh work environments. For those needing enhanced hazard protection there is an option to have the M-2iA-3A/L configured for an IP69K rating. The IP69K version allows this robot to be completely water and dust proof as well as able to withstand high-pressure cleaning. The M-2iA-3/AL can also be suited for use in food production with a food safe option. For this option the m-2ia-3al is configured to meet food sanitary requirements with a high-quality surface treatment and food grade lubricant.

The FANUC M/2iA/3AL utilizes the R-30iB controller and its variants for enhanced programming capabilities.

M-2ia/3S

The FANUC M-2iA/3S is the 4-axis variant among the small parts handling M-2iA Delta robot series. With a reach of 800 mm, the M-2iA-3S offers a larger work envelope for a Delta style robot for achieving high productivity rates. Its payload capacity of 3 kg makes it ideal for performing light weight material handling, pick and place, and assembly applications.The parallel link arm design of the M-2iA/3-S features a single axis hollow wrist. The hollow wrist design allows the FANUC m-2ia/3s to operate at ultra-fast speeds of up to 3500 degrees per second. In addition, the hollow wrist simplifies and protects cabling for air routing and robot signals by running through the arm and wrist directly to the tooling. The parallel link arm mimics human hand dexterity for enhanced operation flexibility.

What makes this Delta robot stand out from others is its durability. Standard features include an IP69K protected wrist and an IP67 protected robot body. The M/2ia/3S can be upgraded to have the entire robot IP69K rated for full hazard protection from water, dust, and high-pressure cleaning. The IP69K option makes this robot suitable for use in cleanroom facilities. The M2iA3S is also available in a white epoxy coating to meet safety standards for food production. The white epoxy makes this robot’s exterior smooth and easy to clean, while food grade grease is used to meet sanitary requirements.

The FANUC M-2iA-3-S is compatible with the intelligent R-30iB controller and its variants, easing robot programming and integration to production lines.

M-2ia/3SL

The FANUC M-2iA/3SL is an ultra-compact long arm 4-axis Delta robot. The M/2iA/3SL is the extended reach version of FANUC’s M-2iA/3S robot. Its reach of 1130 mm allows for an expanded work envelope while still providing the same benefits as the m-2ia/3s. With a payload capacity of 3 kg, the m-2ia/3sl is designed for the handling of light workpieces, exceling at high speed assembly and pick and place applications. In fact, the M-2iA/-3SL can pick and place parts at a rate of 182 per minute.The m/2ia/3sl is able to operate at speeds of 3500 degrees per minute due to its fast-accelerating servo motors. Its parallel link arm and single axis hollow wrist also allows for faster speeds and human hand-like dexterity. The hollow wrist design of the M2iA3SL helps prevent wear and tear of its cabling since the cabling can be routed through the wrist.

The m-2ia-3s-l is one of the most durable Delta robots available with standard features including an IP69K protected wrist and an IP67 protected body. This makes it ideal for clean or wet room environments. There is also an option to upgrade the entire robot to be IP69K rated for complete water and dust protection. In addition, the M-2iA-3S-L can be configured to meet the sanitary requirements for food production. For this option the m-2ia/3s/l is coated in a special white epoxy while food grade grease is integrated with it as well.

The intelligent R-30iB controller, along with its variants, can be paired with the FANUC M2iA/3SL for enhanced programming.

M-2ia/6H

The FANUC M-2iA/6H is a 3-axis ultra-high-speed delta robot. The M-2iA-6H provides a reach of 800 mm and takes full advantage of its entire work envelope. With a 6 kg payload capacity, it has a higher payload than other M-2iA series robots, making the m2ia-6h is capable of handling multiple parts or larger items. Its payload capacity makes this robot stand out from others in its class.The M2iA/6H features the standard parallel link arm of the FANUC spider robots. However, its hollow wrist does not rotate to allow for maximum speed during operation. Due to the lack of wrist rotation the FANUC m-2ia/6h is designed for picking and packaging applications. The hollow wrist design provides enhanced cable protection by routing the cabling through its wrist directly to the tooling. This feature also makes the M/2iA/6H ideal for operation in wet environments along with its wrist being IP69K rated.

The body of the M2iA-6H comes standard with an IP67 rating for preventing the intrusion of water and dust. This IP rating makes it suitable to operate in cleanroom facilities. The compact design of this robot helps to save on space, and it can be inverted for greater workpiece access.

The m-2ia/6h is compatible with FANUC’s R-30iB controller and its variants, allowing users to find the combination most suitable for their productions.

M-2ia/6HL

The FANUC M-2iA/6HL stands out in its class with an extended reach and higher payload capacity than other Delta style robots. With a reach of 1130 mm, the M-2iA-6HL is able to cover more workspace, making it ideal for wider conveyor operations. In addition, the M/2iA/6HL has one of the higher payload capacities amongst the M-2iA series robots with 6 kg. This allows for the handling of multiple parts at once or larger items for enhanced workpiece flexibility.The 3-axis M2iA6HL is designed with a parallel link arm and a hollow robot wrist. The hollow design of the wrist provides cable protection and a simpler setup. The wrist’s IP69K rating makes the M/2iA/6HL ideal for cleanroom environments and capable of withstanding high-pressure cleaning. The robot wrist is also designed with no rotation in order to maximize the operation speed of the robot. Since the wrist does not rotate, the m-2ia/6-hl is best for picking and packaging applications.

The M-2iA/6H/L can be ceiling mounted for space savings and better access to workpieces. Its compact design means users do not have to sacrifice space in order to benefit from this high-speed robot. Users will see reduced cycle times, improved efficiency, and boosted productivity with FANUC’s M-2iA/6H-L robot.

The m-2ia-6hl comes with FANUC’s intelligent R-30iB robot controller. The R-30iB’s variants can also be paired with the m-2ia/6hl including the A-Cabinet, Open Air Cabinet, Mate Cabinet, and Plus models.