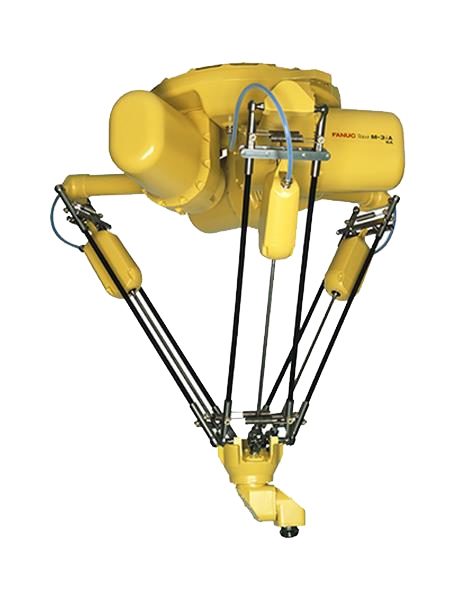

FANUC M-3ia Overview

The FANUC M-3ia high speed delta style robots featuring a 3, 4, or 6-axis structure depending on the model. The M-3iA is designed to handle parts between 6 and 12kg in picking, assembly, and packaging applications. These used delta robots can be found paired with the R-30ia, R-30ib, and R-30ib+ controllers depending on when they were produced. It can be mounted overhead for further space savings along production lines.Additional variations of this robot:

M-3ia/6A

The FANUC M-3ia/6A is a 6-axis high-speed robot designed to maximize versatility and workspace. Featuring a payload capacity of 6 kg, the M3iA/6A can accommodate a larger gripper for handling multiple parts at once or larger items. The M-3iA/6-A is deal for automating demanding assembly, pick and place, dispensing, and packaging applications.The M-3iA-6-A features a longer reach of 1350 mm and takes full advantage of its work envelope. Its parallel link arm is designed with a 3-axis wrist that allows for the freedom of full workpiece and end of arm tooling rotation. The wrist movement of this robot provides dexterity that is similar to the human hand. The 3-axis wrist allows for parts to be fed to the M3iA6A from any side or angle, covering a greater amount of workspace. In addition, this robot can pick up, insert, or twist parts into place with its flexible wrist design. With the dexterity, speed, and work envelope of the M/3iA/6A the number of robots needed on a production line is kept to a minimum, reducing your manufacturing footprint.

The FANUC M/3iA/6/A is protected from both water and dust intrusion with an IP67 rating, making it capable of operating within a number of industries with strict cleanliness standards including electronics and pharmaceutical. There is also a food-grade option available in which the M-3iA/6A is coated in a white epoxy for handling acid and alkaline disinfectants as well as low pressure rinsing. A food-grade lubricant is also used instead of traditional robot grease to meet sanitary requirements making it one of the robots used in the food industry.

M-3ia/6S

The FANUC M-3iA/6S is the 4-axis robot model among the high-speed M-3ia Delta robot series. The M3iA/6S comes standard with a payload capacity of 6 kg, but for those needing more there is an option to upgrade its payload to 8 kg. This allows for the M/3iA/6S to handle multiple parts at once or larger individual items, helping to reduce the number of robots needed on a production line. In fact, the M-3iA-6S can cover multiple conveyers due to its expanded reach of 1350 mm.The m-3ia-6-s is designed with versatility in mind with the capability to perform assembly, picking, packaging, dispensing, and part transfer applications. Its parallel link arm and single axis wrist provide enhanced dexterity and speed. The m3ia/6/s can operate at an ultra-fast speed of 4,000 degrees per second, ensuring a decrease in production times. This robot also saves on floorspace with the ability to mount it overhead.

With an entire robot IP67 rating, the M3iA6S can handle dirty, dusty, or wet environments. Its IP rating allows it to be able to operate in industries requiring strict cleanliness such as electronics, food, and pharmaceutical. An additional food option is available for the FANUC m3ia-6s in which a protective white epoxy coating is applied to its exterior and food-grade grease is integrated as well for the safe automation of food productions.

The M/3ia/6-S is compatible with FANUC’s intelligent R-30iB controller and its variants for an improved user interface and simpler programing.

M-3ia/12H

The FANUC M-3iA/12H is a 3-axis Delta robot in FANUC’s spider M-3iA series. The M3iA/12H is often referred to as a “spider” robot due to its parallel link arm design. Its robot arm configuration allows for a maximum reach of 1350 mm. The longer reach of the M-3iA/12-H provides an expanded work envelope for picking, packaging, assembly, and part transfer applications. In addition, its extended work area reduces the number of robots needed on a production line since more area can be covered by a single robot.As with the other M-3iA series robots, the FANUC M3iA12H operates at high-speeds, making it an ideal robot to reduce cycle times. Its hollow wrist design allows for faster operation as well as provides cable protection. The hollow wrist of the m-3ia/12/h provides easier integration and increased productivity as cable wear and snagging are prevented.

The M3iA12-H is completely IP67 rated for protection from dust and water. This rating also allows it to be safe for food manufacturing. There is a secondary food package available in which the M/3iA/12H is coated in a white epoxy and integrated with food-grade grease. This package makes the m-3ia-12h capable of handling both unpackaged and packaged food items.

Setting up and programming the FANUC M3iA-12H is simplified with the R-30iB controller. The variants of the R-30iB controller can also be paired with this robot.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.