Reducing Cycle Times with Industrial Robots

Manufacturing cycle time is a key performance indicator that can greatly affect a company’s bottom line. It refers to the time spent converting raw materials into finished products and may also be referred to as throughput time. It basically tracks the amount of time from the start of production to the delivery of the finished product to consumers. Manufacturers are always trying to optimize cycle times as the old saying “Time is money” is true. Even the slightest increase in production time can be costly to manufacturers as any delays can affect the number of products available for sale. This lack of consistency in cycle time can make it harder for businesses to budget and predict sales. Optimizing cycle time not only has a positive effect on a company’s profit margin, but also helps them achieve lean manufacturing.

How Robots Improve Cycle Time

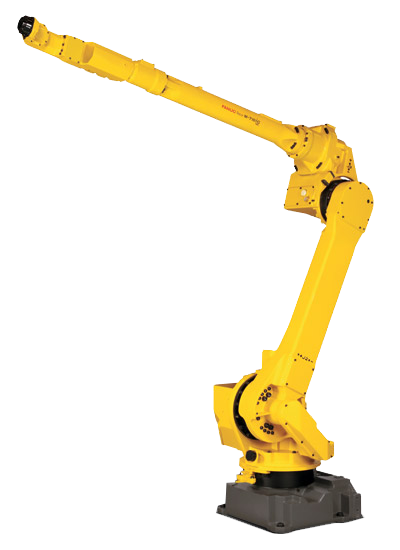

Optimizing cycle time is one of the most common reasons manufacturers integrate their production lines with industrial robots. The FANUC Arc mate 100ic can automate an arc welding application while the FANUC LR Mate 200ic can be used in assembly applications. It is no secret that industrial robots are fast, precise, reliable, and efficient. However, many may not understand how these key benefits of robots play a role in helping to reduce manufacturing cycle times:

- Speed - Industrial robots can operate at much faster speeds than human workers. They are programmed to automatically move from one part to the next with no stoppages. The FANUC M-10ia is capable of transferring 100 parts per minute. With more parts moving through productions, cycle times begin to decrease.

- Precision - Industrial robots operate with extreme precision that is unmatched by human workers. They are able to drill exact holes in parts, produce welds without defects, or cut out intricate designs from workpieces. Their precision eliminates mistakes that can occur during manual work. These mistakes can be very costly to cycle times as time is then taken to correct the mistake or to start completely over. The Motoman MH50 can manufacture parts correctly the first time allowing for cycle times to decrease with fewer mistakes needing to be addressed.

- Reliability - Reliability can be very hard to achieve through manual labor. Workers will vary on their times to complete a task due to breaks, fatigue, or distractions. Robots can operate around the clock without stoppages, allowing them to produce the same number of parts within the same amount of time on each production run. The FANUC R-2000ib can be set up to tend presses with only a minimal amount of manual oversight. Not only does their reliability improve throughput time, but it allows manufacturers to better plan their productions with predictable cycle times and productivity.

- Efficiency - How efficient a process is can greatly effects its cycle time. Having several workers may not necessarily be beneficial to a manufacturing process. With multiple workers involved time may be added on in order to transfer parts from workstation to workstation or there may be more distractions. Industrial robots are capable of handling the workload of 3 to 4 workers along with the capability to perform multiple applications within a cycle run. For example, a FANUC M-710ic/50 can load and unload parts from a machine and then deburr the workpiece to finish it. The cycle time was reduced since the robot completed all steps without needing to wait on others or transfer parts to other