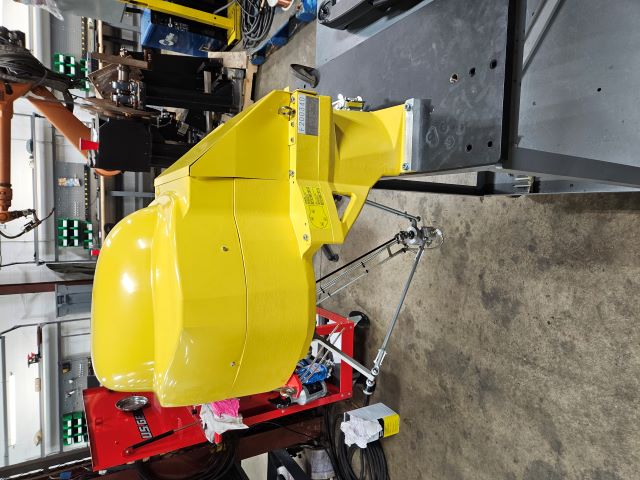

FANUC M-1ia Overview

The FANUC M-1iA is a robotic small parts specialist and part of FANUC’s Delta robot series. Featuring a spider-like body, the m1ia is ultra-compact and ideal for robotic applications requiring a payload of 1 kg or less. This robotic manipulator has a reach of 420 mm and 6 axes. The m-1ia is ideal for users requiring fast handling speeds and versatility, which is why they are often deployed by electronic, fine mechanics, food, medical, and pharmaceutical manufacturers.

The FANUC M1iA is designed with a 3-axis wrist for human-like dexterity and nimble movements. This design allows it to operate with pinpoint precision for many applications including robotic assembly, automated dispensing, and robotic pick and place. The M/1ia is an ideal automation solution for those manufacturing delicate or intricate parts.

The compact design of the M-1ia delta robot makes it the perfect space saver for those with limited room on their production floors and allows for shelf mounting. It can even be detached from its base and integrated directly into machinery, no matter how small they may be. This allows for greater workpiece access. Its versatility combined with its speed makes fast cycle times possible for manufacturers.

The M1i-A is compatible with FANUC R-30iA and R-30ib controllers. Additional options available with the m-1iA include FANUC iRVision, line tracking, and visual line tracking. These options allow the M 1iA to locate and handle irregularly placed objects with ease.

The FANUC M1iA is designed with a 3-axis wrist for human-like dexterity and nimble movements. This design allows it to operate with pinpoint precision for many applications including robotic assembly, automated dispensing, and robotic pick and place. The M/1ia is an ideal automation solution for those manufacturing delicate or intricate parts.

The compact design of the M-1ia delta robot makes it the perfect space saver for those with limited room on their production floors and allows for shelf mounting. It can even be detached from its base and integrated directly into machinery, no matter how small they may be. This allows for greater workpiece access. Its versatility combined with its speed makes fast cycle times possible for manufacturers.

The M1i-A is compatible with FANUC R-30iA and R-30ib controllers. Additional options available with the m-1iA include FANUC iRVision, line tracking, and visual line tracking. These options allow the M 1iA to locate and handle irregularly placed objects with ease.

Robots In Stock

Additional variations of this robot:

M-1iA/.05A

The FANUC M-1iA/0.5A is a delta type handling robot designed for the manufacturing of small parts. Featuring an incredible lightweight design of just 17 kg and a reach of 280 mm. The m 1ia/0.5a is capable of handling intricate parts with its payload capacity of 0.5 kg or less. It is best suited for assembly, material handling, and pick and place applications with its precision and speed.The FANUC M/1iA/0.5A is often referred to as a spider robot due to its innovative parallel link arm design. This industrial robotic arm design along with its 3-axis wrist (in addition to its 6 axes) allows it to operate at any angle. It can also be shelf mounted for incredible space savings and greater workpiece access. The M-1iA-0.5A can also be removed from its stand and integrated into machinery, making it an extremely versatile automation solution.

Its repeatability of 0.02 mm provides incredible accuracy for even complex assemblies. The M1iA0.5A was specifically designed for industries requiring the production of complicated lightweight components including those in the electronics and solar industries.

The FANUC m-1ia/0.5a is compatible with R-30iA, R-30iB, and R-30iB Plus controllers. One controller can be synchronized with up to four M1iA-0.5A robots for ultimate efficiency. FANUC’s SpotTool, iRVision, and Dual Check Safety (DCS) software are additional options available with the m1ia/0.5a for enhanced functionality.

M-1iA/.05AL

The FANUC M-1iA/0.5AL is the extended reach robot variant of the M-1iA/0.5A. With a reach of 420 mm this factory robot offers an expanded workspace while still maintaining the compact design of the M-1iA Delta line. With a payload capacity of 0.5 kg, it is perfect for small part producers and is common among electronic, food, medical, and pharmaceutical industries.Despite its small size, the M1iA0.5AL has 6 axes for high speed and agility. The m-1ia-0.5al is a versatile machine capable of performing many intricate applications including material handling, packaging, pick and place, and assembly. Its versatility doesn’t stop with its functionality, it also offers numerous mounting options. The M-1iA-0.5AL can be tabletop, overhead, shelf, or angle mounted allowing for greater workpiece access and manufacturing flexibility. In addition, it is the perfect small parts solution for those with limited floorspace due to its narrow footprint.

The M/1iA-0.5AL is compatible with FANUC’s compact R-30iB controller along with its variants, the R-30iB Mate and the R-30iB Open Air. FANUC’s ROBOGUIDE programming software allows the M 1iA 0.5AL to be programmed offline. Additional software options are available for the m/1ia-0.5al for enhanced operation including iRVision and Dual Check Safety (DCS).

The M-1iA/0.5AL makes automating intricate part assemblies possible while improving operation efficiency, speed, and productivity.

M-1iA/.05S

The FANUC M-1iA/0.5S is the 4-axis variant of the M-1iA Delta robot line. Featuring a payload capacity of 0.5 kg, the m-1ia-0.5s is a small parts specialist. The compact design of the M1iA0.5S makes it the perfect automation solution for those tight on space. It is extremely lightweight, weighing in at just 14 kg. This makes it ideal for tabletop, angle, or overhead mounting options. Its base can also be removed to allow it to be installed as a stand-alone robot.Despite its small size and light weight, the M-1iA-0.5S can operate at extremely fast speeds of up to 3000 degrees per second. With rates that fast the FANUC M/1iA/0.5S is sure to reduce cycle times and increase productivity. Its parallel link arm is designed with a single axis wrist, providing human-like dexterity and agility. This makes the m/1ia-0.5s ideal for intricate applications such as pick and place, dispensing, assembly, and material handling. In addition, the M 1iA 0.5S utilizes its entire work envelope with no dead zone technology and straight-line motion from point to point.

The m/1ia-0.5s is compatible with FANUC’s R-30iA and R-30iB controllers. It can also be paired with the variants of the R-30iB controller including the newest model, the R-30iB Plus.

The m-1ia/0.5s is the ultimate high-speed small parts robot, providing versatility and precision to intricate parts assemblies.

M-1iA/.05SL

The FANUC M-1iA/0.5SL is the long arm version of the M-1iA/0.5S. With a maximum reach of 420 mm, this robot provides an expanded work envelope for those looking to cover more space with 4 axes of motion. The m-1ia-0.5sl is best suited for handling small parts with its payload capacity of 0.5 kg or less.The spider-like design of its parallel link arm and single axis wrist allow the FANUC M/1iA/0.5SL to operate with human hand-like dexterity. Not only does this arm design make the m-1ia/0.5s/l extremely nimble, but it also allows for incredibly fast operating speeds. The m1ia0.5sl has a maximum speed of 3000 degrees per second, making it the perfect solution for those looking to cut down on cycle times. The M 1iA 0.5 SL can make quick work of small part assembly, part transfer, and pick and place applications.

As with other M-1iA Delta series robots, the M-1iA/0.5S-L features a compact and lightweight design. With a weight of 17 kg it is one of the lightest models in FANUC’s M-1 series. This allows for it to operate in tight spaces and for numerous mounting options including shelf and ceiling. It can also be integrated with a reversible stand for enhanced versatility.

The FANUC M-1iA/0.5S/L comes with the intelligent R-30iB controller. It is also compatible with the R-30iB variants including the Mate Cabinet, Open Air Cabinet, and Plus models.

M-1iA/.05H

The FANUC M-1iA/1H is the 3-axis model of FANUC’s small parts specialist M-1 series. Featuring a payload capacity of 1 kg or less, the M-1iA-1H is ideal for the handling of light or intricate parts. This robot is commonly deployed for pick and place applications but can also be programmed for packaging and part transfer applications. In fact, the m/1ia/1h was specially designed by FANUC for manufacturers in the electronics, solar, and mechanic devices industries since they often work with small part assemblies.The M1iA-1H features a reach of 280 mm but is designed to make the most use out of its workspace. What makes this robot unique from the others in the M-1 series is that it is programmed to function strictly within its parameters. This enables line staff to work directly side by side with the M-1iA-1H without compromising their safety. This also provides manufacturers with greater versatility within their production lines.

The parallel link arm design of the m1ia1h allows for incredibly fast cycle times and pinpoint precision. Its robot body features a compact design for space savings and flexible mounting options including floor, ceiling, and angle. Manufacturers do not have to worry about making room on their production floors for the M-1iA/1-H with its mounting versatility and narrow footprint.

The M 1iA 1H is compatible with FANUC’s R-30iA and R-30iB controllers, for an enhanced user experience.