Robotic Degrees of Freedom

One of the key characteristics of an industrial robot is the number of axes it has. It is often one of the first items listed when viewing a robot’s specifications. However, many may not understand the importance of the axes and how they control a robot’s range of motion. Each axis of a robot represents a degree of freedom or in simpler terms an independent motion. Each axis allows a robot to gain a degree of freedom, meaning it has increased functionality. The more axes a robot has, the more degrees of freedom it has which allows it access to greater amounts of space.

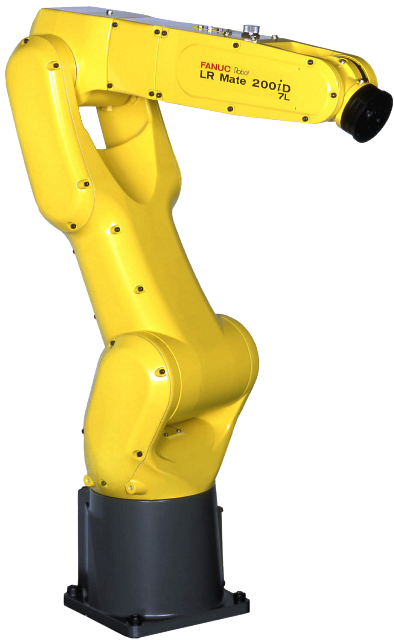

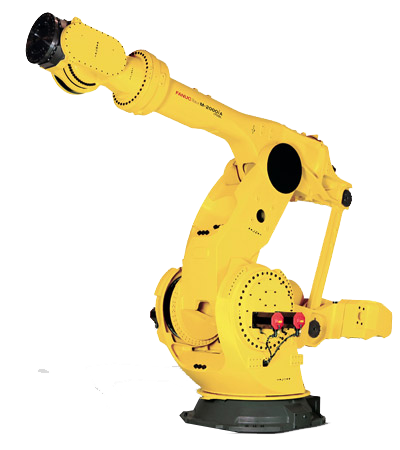

The most common robots have between four to six axes, but they can have a little as one axis or as many as ten or more. Six-axis robots such as the FANUC M-10ia or the FANUC R-2000ib are heavily utilized in industrial settings because they provide more functionality with six degrees of freedom. The six-axis robot is designed to mimic the human arm, since human arms have six degrees of freedom. Having six degrees of freedom also allows every angle of a unit of space to be reached. Below is a breakdown of the degree of freedom provided by each axis of a robot:

- Axis 1 - Axis 1 allows the robot to rotate from its base.

- Axis 2 - Axis 2 provides the robot with forward extension and back extension of its lower arm.

- Axis 3 - Axis 3 provides the robot the ability to raise and lower its upper arm.

- Axis 4 - This axis can rotate the robot’s upper arm in a rolling motion.

- Axis 5 - Axis 5 raises and lowers the wrist of the robot’s arm.

- Axis 6 - This axis can rotate the wrist of the robot arm.

As mentioned above, six-axis robots are designed to mimic human arm movements and provide the same degrees of freedom as human arms. This makes them ideal solutions from taking on repetitive, tedious, and even dangerous manufacturing jobs once only held by humans. They can perform all the same motions as their human counterparts without tiring or risking their safety. Their extended reach enhances their range of motion and when combined with their numerous degrees of freedom allows for greater access to even hard to reach objects.