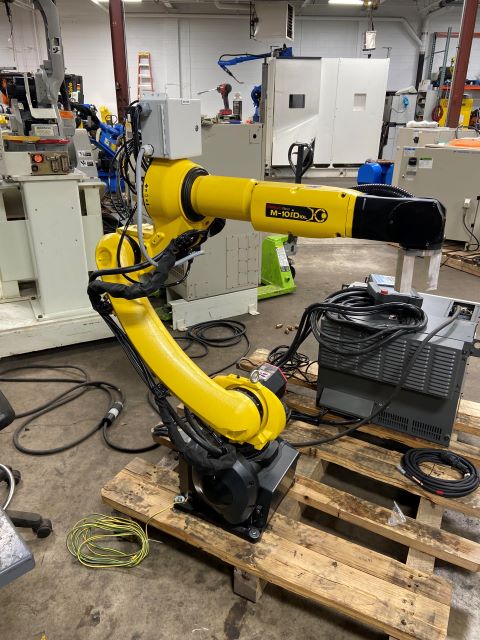

FANUC M-10iD/10L Overview

The FANUC M-10iD/10L an extended reach indstrial robot is designed for various light robotic material handling applications. This high speed robotic manipulator is used in many applications including automated assembly, robotic machine tending, and automated injection molding. This FANUC robot has a longer reach, higher payload, and increased accuracy over the FANUC M-10ia-7L. The M10iD/10L is a six axis robot with servo driven motors. The FANUC M10iD/10L is available in the FANUC R-30ib Plus controller. This material handling robot can inverted, floor mounted, angle mounted, or installed on a track to give it complete flexibility. Purchasing a used M-10id-10L industrial robot allows for maximum flexibility in that it can be integrated with a welder and converted into a FANUC Arcmate 100id/10L. Purchasing a used FANUC robot such as the FANUC M 10id/10L robot help increase the safety of your work environment.This articulated robot is similar in reach and payload to the ABB IRB 1600, KUKA KR6, and Yaskawa Motoman MH12. For applications that do not require the reach of this handling robot the standard M-10id/12 can be used. For applications requiring a larger reach and payload, either a FANUC M-20ia or M-20id/25 can be used.

Looking to sell a used FANUC robot similar to this model? Click Here: Selling a used robot