Industrial Robot Cost

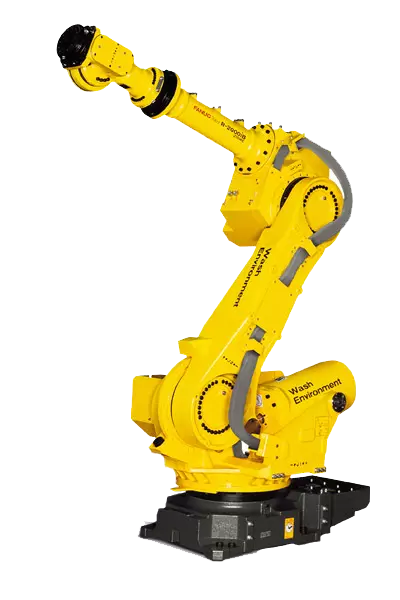

The use of industrial robots has grown considerably over the last several years. Robots are now becoming the top choice for industrial automation in manufacturing. Their speed, versatility, and accuracy are extremely advantageous and allow for complete manufacturing optimization. Articulated robots were once mainly used in the automotive industry, but have since branched into numerous others including aerospace, food, medical, and electronics. Advancements in robotic technology, artificial intelligence, force sensors, and software have taken six axis robots from simplistic rigid machines to intelligent devices with the ability to automate most production related tasks regardless of complexity.

The number one question of companies looking to automate with industrial robots is often “What is the cost?” Industrial robot cost is one of the main factors that determine if it is feasible for a company to implement robotic automation for their manufacturing. Fortunately, due to the rise in industrial robot use, advancements in robotic technology, and increased competition amongst robot brands, the costs for robots have decreased in recent years. New industrial robots typically start at around $25,000 and can go over $100,000. Costs are dependent upon not just the robot itself but the controller, teach pendant, software, EOAT, and additional options. All of these peripherals can have a significant impact on the final cost of a robot.

You should not let the price tag of an industrial robot deter you from robotic automation as there are other options that are more affordable than purchasing a brand-new robot. One option is to consider buying a used robot. Many people looking to automate wonder "what does a used robot cost?" Used robots can save buyers between 40% to 60% of the price of a new robot. Robots that have been well maintained can be in operation for several years or decades. Take for instance the FANUC Lr Mate 200ib and the Motoman HP20, both are older models but are still widely used across manufacturing floors around the world. Purchasing a used robot does not mean you are sacrificing on quality. Used industrial robots provide the same benefits as new robots at a fraction of the price. The FANUC Arcmate 120ic can produce the same welds at similar or the same cycle time as the Arcmate 120id.

Another more affordable option for those looking to automate with robots on a budget would be to consider buying a collaborative robot. Cobots are typically smaller than industrial robots and offer less payload capacity, but they tend to be more affordable. Cobots are advantageous since they can directly assist workers without the need for barriers. The Universal UR10 features rounded edges and advanced safety sensors for the safe collaboration with workers.

Industrial robot cost is mainly dependent upon the size of the robot, number of axes, safety features, and end-effector. Many of these factors will be determined by the application being automated and will have a big impact on the final cost. Adding a robotic gripper to a FANUC M10ia could add a few thousand dollars to the cost, depending on the gripper. Many used FANUC robots for sale include a gripper if they were previously performing applications such as automated pick and place or robotic assembly. Opting to purchase a used robotic system will provide considerable savings on all of these factors.

When considering the cost of an industrial robot it is also important to consider the operational savings that will be obtained through robotic automation. Robots are investments that will pay for themselves in the long run through shorter cycle times, increased productivity, higher product quality, and reduced utility and labor costs. These factors allow companies to capture their ROI relatively quickly.