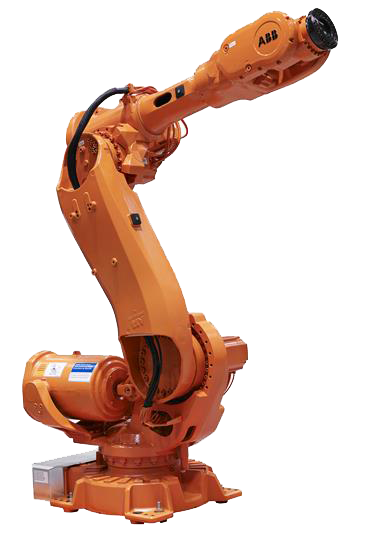

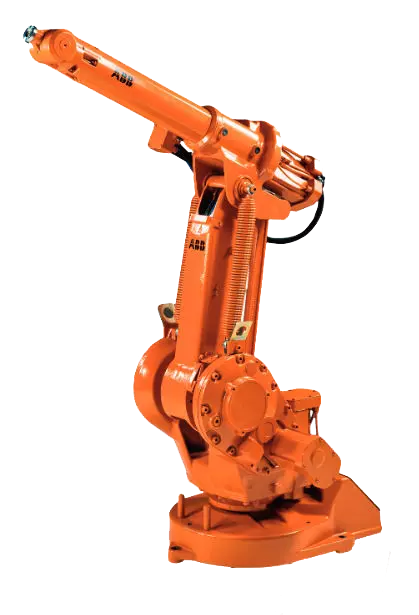

ABB is one of the top robotic manufacturers in the world with their robots serving many industries. The following is a list of some of their most popular industrial robot models.

- IRB 120 - ABB’s IRB 120 is one of their most successful models that has been around for a number of years. Featuring a compact and lightweight design that makes integration easy in a variety of industries including food, pharmaceutical, electronic, and machinery. Its 3 kg payload capacity makes it ideal for light material handling, assembly, and pick and place applications.

- IRB 140 - The ABB IRB 140 may be compact, but it is a powerful multipurpose robot capable of handling payloads up to 6 kg. This robot can handle arc welding, assembly, spraying, machine tending, packaging, material handling, and deburring applications. Its arm comes standard with IP67 rated protection, allowing it to operate in conditions with high dust or liquid exposure.

- IRB 1410 - The IRB 1410 is designed for arc welding, material handling, and machine tending applications. This model is popular with its low noise levels due to its robust design. It also provides longer runtimes in between routine maintenance, allowing users to achieve maximum productivity.

- IRB 1600 - ABB’s IRB 1600 has become one of their most popular robots with its incredible cycle times. Cycle times for material handling and machine tending processes can be reduced by up to 50% with this robot. This is key for higher throughput and productivity rates. The IRB 1600 is known for its reliability and high workpiece quality.

- IRB 2400 - The IRB 2000 series of robots features models designed to optimize arc welding, machine tending, and material handling processes. The IRB 2400 series is comprised of the IRB 2400L, IRB 2400-10, and the IRB 2400-16. Payload capacity ranges from 7 kg to 16 kg for lightweight tasks. All versions can be floor or ceiling mounted and come standard with IP54 protection.

- IRB 4600 - ABB’s IRB 4600 robot family features several multipurpose models designed for drilling, material handling, material removal, and dispensing applications, among many others. Payloads in this series range from 20 kg up to 60 kg. The IRB 4600-20 and the IRB 4600-45 are two of the top models form this series designed for reducing cycle times by 25%.

- IRB 6640 - The ABB IRB 6640 robot series features models such as the IRB 6640-180 and the IRC 6640-235. This line of strong and durable robots offers a payload capacity range of 135 kg up to 235 kg for heavier applications. The IRB 6640 robots provide extended work envelopes with the ability to bend completely backwards allowing for flexible operation. In addition, these robots feature collision resistance, ensuring safe operation. With IP67 protection these robots can be deployed for deburring, high pressure washing, and water jetting applications.

- IRB 7600 - The IRB 7600 robot series offers several variants including the IRB 7600-500 and the IRB 7600-325 for heavy lifting applications. Payload ranges for this series start at 150 kg and go up to 500 kg, making them some of ABB’s strongest robots. These ABB robots are automating automotive manufacturing, foundry operations, and many other industries. Despite the handling of very heavy payloads, the IRB 7600 robots are designed to ensure the safety and protection of any personnel or equipment around their operation with SafeMove2 technology.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.