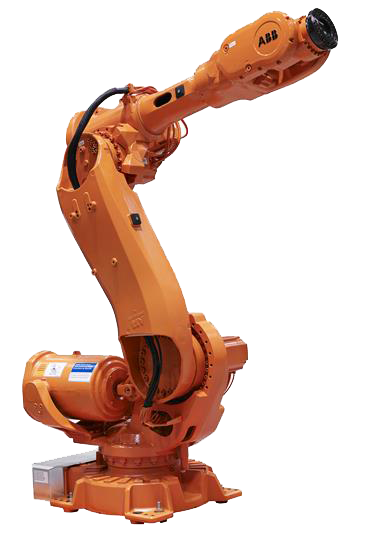

ABB 6640

ABB’s IRB 6640 robot series features a line of highly reliable and speedy 6-axis robots designed to ease applications requiring high payloads and long reaches. The IRB 6640 series is composed of ABB’s latest generation of heavy lifting robots that were designed to replace their highly successful IRB 6600 robot line. These used robots feature heavy payloads with ranges from 130 to 235 kg to be able to handle the heaviest of parts. They also provide an extended reach with ranges between 2550 to 3200 mm. When designing the IRB 6640 robot line ABB made sure to improve upon the IRB 6600 series. Maintenance requirements are reduced with robots like the ABB IRB 6640-205/2.75 in the 6640 series with simplified forklift pockets and more space within the foot area of the factory robots. They reduced the weight of the articulated robots within this series by almost 400 kg from their predecessors to further ease maintenance and allow for easier installation. These six axis robots utilize ABB’s intelligent IRC5 controller for enhanced motion control, communication, and application programming.

As mentioned above the ABB IRB 6640 robot line is designed for performing heavy payload and long reach applications. The long reach of these industrial robot arms, such as the ABB IRB 6640-130/3.2, provides them with the capability to operate with a large work envelope. Their industrial robot work envelope is further expanded by their ability to bend fully backwards, offering greater flexibility within production lines. Even though the IRB 6640 robot manipulators can only be floor mounted their backwards capability helps to provide greater access to workpieces and expands their motion. The extended reach and motion make them a great choice for those with dense production lines, especially since ABB robots are known for their collision resistance. This allows them to work amongst additional ABB robots or peripherals without interference. Their inertia capacity also allows for the handling of wide or bulky parts.

On top of offering different work environment options, these manufacturing robot arms are also capable of completing a variety of applications. The ABB IRB 6640-235/2.55 is a perfect choice for automated spot welding applications with its incredible precision. While the ABB IRB 6640-180/2.55 is great for palletizing robot applications with its high payload capacity. Other applications covered by this series include: automated machine tending, packaging, pick and place, press tending, and material handling. The upper industrial robotic arm extenders and different wrist modules allow for application specific customization. These units can also be integrated with external devices such as robotic transfer units, motors, and robotic positioners.