Advantages of Large Robots

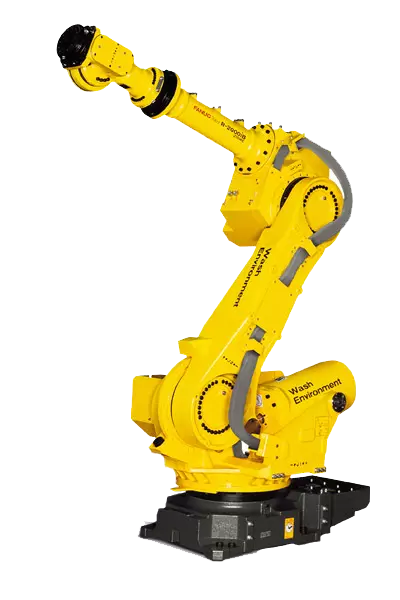

In the early years of industrial robots, large robots were the predominant class. As robotic technology has advanced new and smaller types of robots have been developed. Today small industrial robots have become one of the biggest trends, but large industrial robot arms still hold their place in the automation world. Articulated robots are considered large if their payload capacity is 150 kg or more and their reach is equal to or exceeds 2,000 mm. The FANUC R-2000ib/165F is an example of a large industrial robot.

In the early years of industrial robots, large robots were the predominant class. As robotic technology has advanced new and smaller types of robots have been developed. Today small industrial robots have become one of the biggest trends, but large industrial robot arms still hold their place in the automation world. Articulated robots are considered large if their payload capacity is 150 kg or more and their reach is equal to or exceeds 2,000 mm. The FANUC R-2000ib/165F is an example of a large industrial robot.

While small robotic manipulators have become quite popular there are still many advantages to automating with a larger robot. These advantages include:

- • High Payload Capacity - The high payload capacity of large robot manipulators is a big advantage as they are able to handle heavy workpieces and be integrated with heavier tooling as well. The FANUC M-410ib/450 is ideal for heavy payload tasks such as automated robotic palletizing. Large payload robots can safely and effectively move heavy parts. This spares workers from the potential hazards of working with large parts or operating equipment to move such parts for a safe work environment. Large robots are often used in the automotive and aerospace industries for material handling automation.

- • Long Reach - Large industrial robots feature long robotic arms which provides them with an extended reach. These six axis robots are able to operate with large work envelopes allowing them to cover a greater amount of workspace. A long reach also provides them with the capability to work with large parts. With large robots, investments in additional equipment such as risers or track systems may not be necessary, reducing the total cost of a robotic system.

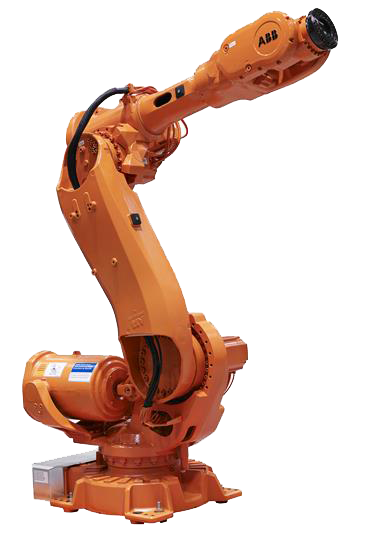

- • Versatile - Industrial robots provide flexible automation as they are reprogrammable and can automate multiple types of applications. Forklifts and other traditional material handling equipment are designed for one specific task. A ABB 6640-180/2.55 can lift heavy parts, transfer them, and place them on pallets. Large articulated robotscan be repurposed when manufacturing needs change, allowing them to be used for multiple projects. Large robots can automate material handling, palletizing, part transfer, and machine loading among many other applications.

- • Full Range of Motion - The majority of large robots are configured with six axes which gives them six degrees of freedom for a full range of motion. This means they can access every angle of a unit of space, similar to the human arm. With their range of motion more movements are available to them for better part and work envelope access. Their full range of motion makes them ideal for automating manual processes.

- • Footprint - When thinking about a large factory robots, you may think their footprint would naturally take up a large amount of space and be a disadvantage. However, just because a manufacturing robot arm is considered large does not mean its footprint is. FANUC’s R-2000 robots are considered to be large robots, but the reason they have been so successful is because they feature a compact footprint for their class. The footprint for the R-2000iD series has been reduced further. The FANUC R-2000id/165FH has a footprint that has been reduced by 23% from its predecessors.

Check out these popular Advantages of Large Robots

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling a used robot.