Large Industrial Robots

Industrial robots vary considerably by structure, size, number of axes, how much they can lift, how far they can reach, and what they can automate. Finding the right robot for your production needs will depend upon the type of application being automated. For heavy lifting applications, a large industrial robot will most likely be the best option.

Industrial robots vary considerably by structure, size, number of axes, how much they can lift, how far they can reach, and what they can automate. Finding the right robot for your production needs will depend upon the type of application being automated. For heavy lifting applications, a large industrial robot will most likely be the best option.

Large industrial robots in general feature an articulated structure with four to six axes. They typically are capable of handling high payloads and have longer reaches than their smaller counterparts. An articulated robot that is consider a heavy payload robot will usually have a larger footprint. Large robots have payload capacities over 150 kg. Some large robots even have payloads that exceed 1,000 kg for extremely heavy lifting. Most large robots will feature extended arms with reaches exceeding 2,000 mm.

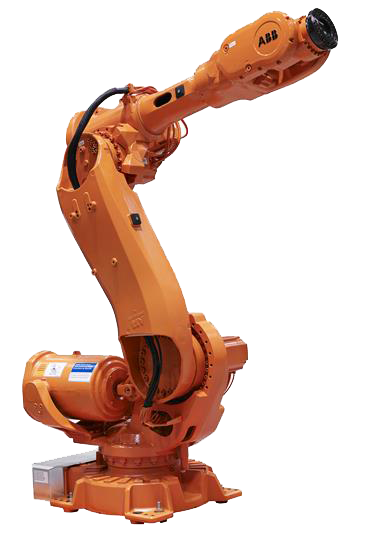

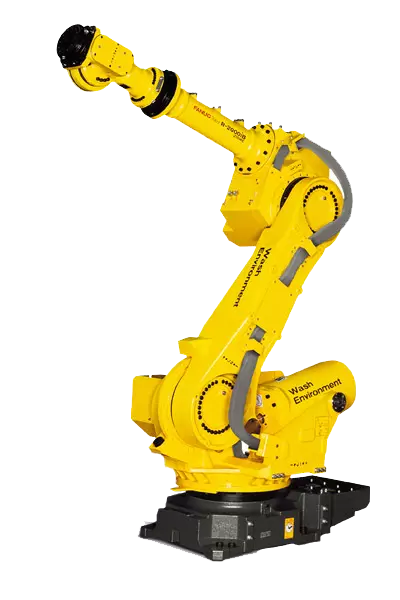

Top robotic manufacturers FANUC, Yaskawa Motoman, ABB, and KUKA all produce incredibly strong, large industrial robots for the automation of heavy-duty applications. FANUC’s M900ia and R-2000ib are two of their heavy lifting robots. While the Motoman MH250 from Yaskawa is one of their stronger models. ABB 7600 robots can lift up to 500 kg.

Large robots are capable of lifting and moving heavy, bulky parts or equipment with ease. Their multipurpose capabilities make them more valuable than traditional material handling equipment, such as forklifts. They can be programmed for multiple applications and can handle a variety of parts. The automotive industry and aerospace industry both involve the operation and handling of heavy equipment and parts, making them ideal for large robot automation. In the automotive industry large robots are used to move entire cars safely and securely.

The heavy payload of large robots is one of their main benefits. Humans are limited when it comes to how much they can lift, while traditional material handling equipment may not always be the most secure lifting method. Industrial robots are programmed for accuracy, ensuring all parts are handled securely, preventing damage to parts or accidents on manufacturing floors. Automating your heavy lifting applications with large robots will improve the safety of your workforce. Workers are relieved from lifting heavy objects or from having to operate lifting equipment, both of which can be dangerous.

Another advantage of large robots is their bigger work envelope. Since most large robots have extended reaches, they can cover a greater amount of workspace. This prevents manufacturers from having to invest in additional equipment such as track systems or robotic risers to expand the work envelope.

Large robots are incredibly versatile with their multipurpose capabilities. Forklifts and other traditional material handling equipment can only be used for specific processes. A large robot like the FANUC R-2000ib/165F can automate palletizing, material handling, or packaging making it a much more cost-effective manufacturing solution.