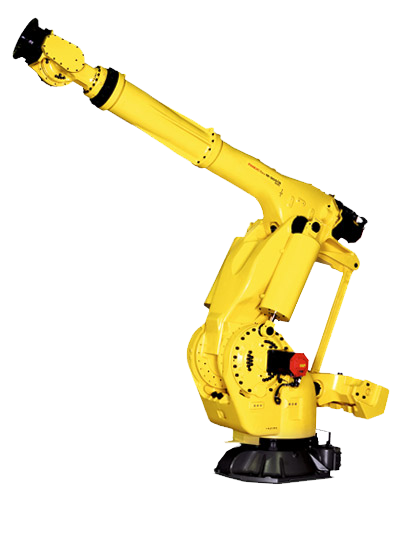

FANUC M-900ia

The robots that comprise the FANUC M-900iA robot series are some of the toughest and heaviest lifters in the robotic industry. These 6-axis industrial robots are designed for heavy payload applications and also feature a wide work envelope. In fact, they are one of the highest payload robots on the market with ranges between 150 to 700 kg. This makes models like the FANUC M-900ia/350 an excellent choice for manufacturers that work with large or heavy workpieces. Not only are they heavy lifters, but also provide an expanded work envelope with their long reach of up to 3625 mm. Their work envelope is further extended with various mounting options including floor, ceiling, angles, and wall. While their J3 slim wrist design allows for access to workpieces in tight, confined spaces.

The FANUC M-900iA robots are often viewed upon as best in their class due to their high reliability and incredible precision. The manufacturing of large parts can be quite challenging, requiring tremendous manpower and longer cycle times. Robots such as the 260L in the M-900iA series make working with these parts a breeze with their user-friendly interface. Their high repeatability and speed make them a favorite for those with high volume productions particularly in the automotive industry. Manufacturers can watch their productivity levels rise with the adoption of robots from the M-900iA series while workers can be removed from taxing applications.

The robots in the M-900iA series are designed with incredible structural rigidity for the capability of handling forceful and heavy applications with the upmost accuracy. Their parallel link arm allows for compatibility with large grippers for easy and precise handling of bulky workpieces. The use of large grippers provides improved carrying capacity along with better wrist movements and inertia to increase throughput rates. FANUC M-900iA robots also feature software designed for high inertias for speedy cycle times no matter how big the workpiece.

These used fanuc robots prove to be quite the workhorses with not only the amount they can lift and reach, but also with their ability to withstand some of the toughest work environments. Their wrist is IP67 rated to be sealed against dust or water. Their wrists are further built to withstand harsh elements with the motors mounted to the robot shoulders for extra protection. Their shoulder mounted wrist motors allow for increased speed since they feature improved cooling. The outer robot arm is stationary to simplify the hose and cable dressout, which helps to prolong the robot runtime. The simpler, smarter design of M-900iA robots allows for longer runtimes between required maintenance, which keeps operations moving for extended periods of time without production delays. Maintenance costs are also kept to a minimum as these robots require few spare parts.

With the FANUC M-900iA robot line it would be hard to not be able to find a model to suit your production needs since they are incredibly versatile and can perform numerous applications. The FANUC M-900ia/400L is capable of handling applications needing force such as: cutting, polishing, deburring, and drilling. While the FANUC M-900ia/600 is perfect for heavy material handling processes. Other applications covered by this robot series include: palletizing, packaging, pick and place, assembly, material removal, dispensing, spot welding, and coating.