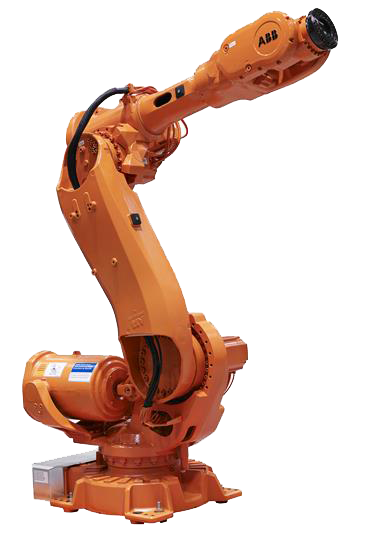

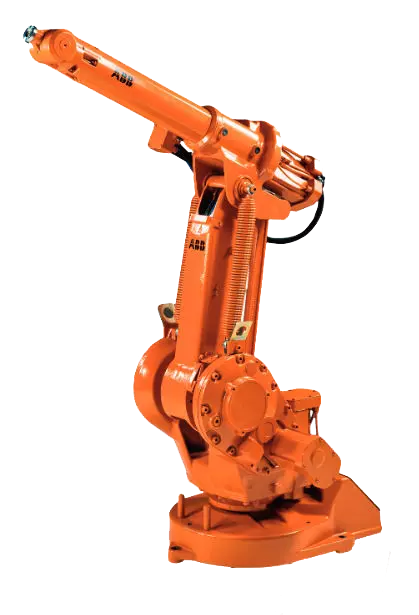

ABB is one of the top robotic manufacturers in the world. The Swiss based industrial robotic arm manufacturer has been producing industrial robots for several decades and continues to advance the industry. ABB is known for manufacturing innovative multipurpose industrial robots capable of automating most production applications including welding.

While ABB does not have a specific line of articulated robots dedicated to solely welding like their competitors Yaskawa Motoman and FANUC, they are still considered one of the world leaders for welding automation. Since their industrial robot arms are multipurpose, they can automate applications such as material handling, material removal, and assembly in addition to welding. One ABB robot could automate an entire metal fabrication process for streamlined manufacturing. ABB robotic manipulator are commonly used as handling robots.

Just about every robot series from ABB features six axis robots that are capable of automating welding applications. Robots from their 100 series, 1000 series, and 2000 series feature lighter payloads ranging from 3 kg up to 20 kg making them ideal for arc welding applications. The ABB IRB 1600 can automate MIG processes. Those with compact work envelopes could use the ABB 140 for arc welding automation since it features a shorter robotic arm. ABB’s heavy lifting robots from their 6000 and 7000 series can be used to automate spot welding. These heavy payload robots feature high payloads starting at 130 kg and going over 500 kg. With heavy payloads, these robots can handle working with large workpieces and heavy spot welding tooling. They also feature longer reaches for an expanded work envelope. The ABB 6640-205/2.75 is a spot welder from the 6000 series while the IRB 7600-150/3.5 is another spot welding robot from the 7000 series.

ABB also manufacturers their own robotic welding cells with the FlexArc series. The FlexArc series features several pre-engineered weld cells designed for one or two ABB welding robots. Each cell comes with safety equipment, welding peripherals including the torch and power supply, and a robotic positioner. Turnkey workcell with robots are a cost-effective alternative to customized cells for optimizing a welding process.

ABB’s welding robots are compatible and can be easily integrated with welding equipment from Fronius and Miller. The ABB 2600-12 is compatible with the Fronius CMT 3200 power supply. ABB’s 4600-20 integrates nicely with the Miller Autoaxcess 450-di . Fronius and Miller are both top welding equipment brands, simplifying the setup process since their welding equipment is widely available. The compatibility of ABB’s robots with these brands also makes for easy robot replacement for those with pre-existing welding systems.

Automating with an ABB robot will significantly improve your welding process. Welds will be accurate and higher quality ensuring they are incredibly durable. Higher throughput rates can be achieved with ABB welding robots which will in turn raise productivity rates. Their high repeatability ensures precision allowing welds to be uniform from one workpiece to the next. Material waste can be reduced with the precision of ABB robots. Higher throughput with reduced errors will cut down on cycle times. Parts can be welded in less time than through manual methods. All of these benefits will translate into reduced production costs and a more efficient welding process.

Robots Done Right |

Used Robot Sales |

ABB Welding Robots

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.