Robots Done Right |

Used Robot Sales |

FANUC Collaborative Robots

Cobots, also known as collaborative robots, are robots that are designed for direct human interaction within a shared work area. Cobots differ from traditional industrial robots in that they can operate within close proximity to workers without the need for safety barriers. Collaborative robot safety features allow for the safe, direct interaction of cobots with humans. These safety features include rounded edges, elimination of pinch points, limits on speed and force, and the use of safety sensors.

Cobots were first developed in 1996 and were initially used in the automotive industry for final assembly tasks. Since then several of the top robotic manufacturers in the world have developed cobot product lines. In 2015, FANUC entered the cobot world with their CR collaborative robot series.

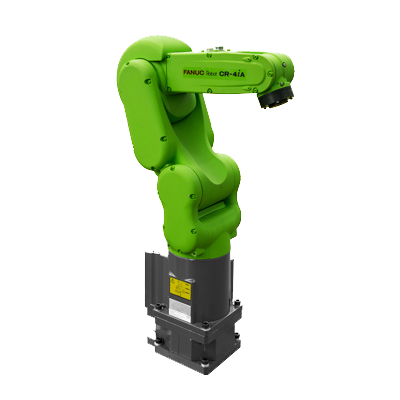

FANUC’s CR collaborative robot series stands out from their traditional yellow industrial robots with their bright green exteriors. Their cobot series features five collaborative robots. These cobots range in payload capacity from 4 kg up to 35 kg. All have six axes for a flexible range of motion that is ideal for many manufacturing tasks.

FANUC cobots are designed for the safe operation and collaboration with human workers. The CR series cobots are equipped with contact sensor technology that will immediately stop robot operation should it come into contact with a person or object. In addition, FANUC CR cobots provide customizable speed and safety settings, allowing users more flexibility and to make adjustments best for their manufacturing processes.

FANUC CR cobots can be programmed easily by anyone, regardless of robot experience with their hand guidance feature. CR cobot arms can be manually guided by hand through desired application paths. The cobots will then be able to autonomously repeat those movements over and over. CR robots can also be deployed to lift heavy objects for workers through their hand guidance technology.

The CR-35iA was the first cobot to be released by FANUC. The FANUC CR-35iA offers the heaviest payload capacity of any collaborative robot with the ability to lift up to 35 kg. The CR-35iA is covered in a soft rubber exterior coating for additional collision protection.

Since the creation of the CR-35iA, FANUC has released four additional collaborative robots, the CR-15iA, CR-7iA, CR-7iA/L, and the CR-4iA. The CR-7iA, CR-7iA/L, and CR-4iA are designed for lightweight tasks with payloads of 7 kg and 4 kg. The CR-15iA fills in the gap between the other CR models with its 15 kg payload capacity.

FANUC cobots are ideal for automating tedious, repetitive, and highly manual manufacturing tasks. These include automated dispensing, robotic pick and place,automated packaging,robotic palletizing, machine tending,robotic assembly, and inspection applications. They have been deployed to automate manufacturing processes across several industries including the automotive, distribution, metalworking, and packaging industries.

FANUC collaborative robots provide a reliable automation solution that can significantly improve production lines. The elimination of safety barriers allows CR robots to directly assist workers. Manufacturing processes as a result become more efficient and productive while cycle times are reduced. FANUC’s CR cobots are revolutionizing manufacturing by proving robots and humans can work alongside one another.

FANUC CRX Robot Series

The FANUC CRX robot series is the latest generation of FANUC collaborative robots. This line builds upon the success of FANUC’s first collaborative robot line, the CR series. Initially the CRX line featured two cobots, the CRX-10iA and the CRX-10iA/L. Last year FANUC added three additional collaborative robots for a total of five cobots within the series. The CRX robots are ideal for robotic manipulator users of any experience level, but especially those new to robotics. Their intuitive use makes them incredibly user friendly and an excellent supplement for manual labor.Cobots

As mentioned above there are now five collaborative robots within the CRX series. These include:- • CRX-5iA - The CRX-5iA is the smallest of the series with a payload of 5 kg and a reach of 994 mm.

- • CRX-10iA - The CRX-10iA features a payload of 10 kg and a reach of 1,249 mm.

- • CRX-10iA/L - The CRX-10iA/L is the extended reach version of the CRX-10iA. It has the same payload at 10 kg, but a longer reach of 1,418 mm. It also features a unique under flip motion.

- • CRX-20iA/L - The CRX-20iA/L has a maximum payload capacity of 20 kg and a reach of 1,418 mm. Like the CRX-10iA/L it also features the under flip motion.

- • CRX-25iA - The CRX-25iA is the largest of the CRX robots. It has a 25 kg payload capacity and a reach of 1,889 mm.

Features

Like FANUC’s first collaborative robot line, the CRX robots are designed to be able to operate safely around workers without any barriers. They feature a smooth rounded exterior, light mass, and compact footprint to minimize any contact. They also have built-in sensors for detecting objects and people. When either are sensed the CRX cobots will immediately stop their operation in order to prevent collisions.Programming is made easy with two user-friendly options. FANUC CRX robots can be programmed using hand guidance where the industrial robot arm is manually guided through the way points of an application. They may also be programmed with FANUC’s latest teach pendant technology that features a drag and drop interface.

Maintenance requirements have been simplified and reduced. The CRX cobots are designed to operate for a full 8 years without requiring maintenance on motors, reducers, sensors, cables, and grease during that time. Less maintenance means more uptime for the cobot and less upkeep for users.

The CRX cobots feature a white epoxy exterior that makes them rust and chemical resistant. They also feature dust and oil leak protection, making them suitable for work environments such as food processing.

The CRX cobots feature a compact footprint and are paired with the R-30iB Mini Plus controller which allows for additional space savings. The small footprint of the CRX cobot system allows them to be easily integrated into any factory. They also run on standard 120V power.