In today’s world it is hard to find a sector or industry that does not utilize some form of automation. Robotic automation has grown extensively over the past several years. Each year more companies implement industrial robots. As the number of industrial robots grow so do the number of robotic manufacturers. However, one of the most popular robotic brands remains ABB.

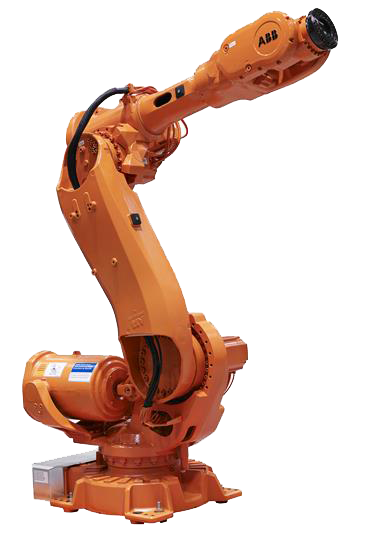

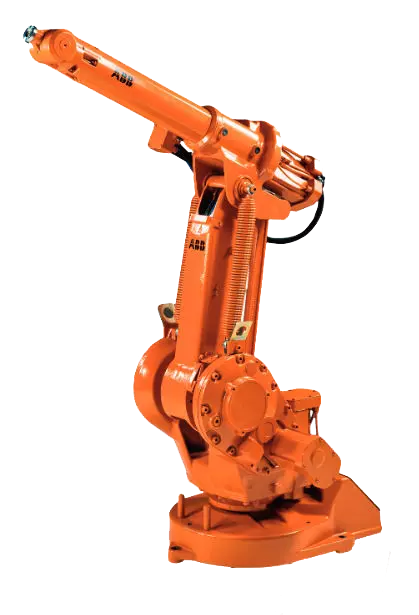

ABB has a long history in the robotic industry. They are known for producing innovative, energy-efficient, and powerful industrial robots which is why they have remained one of the top brands. ABB manufactures articulated, delta, SCARA, and collaborative robots. Many of their articulated robots feature multipurpose capabilities allowing them to serve many different uses.

ABB robots can be used to automate part of a production process or an entire factory. ABB robots are ideal for automating repetitive, dull, time consuming, or dangerous tasks. Implementing the ABB 2400 along a production line can turn a manual process into an automatic one by reducing or eliminating the need for any human intervention.

The versatility and flexibility of ABB robots means they can be used in a variety of ways by a variety of industries. ABB robots are currently being used in the automotive, food, beverage, metals, mining, oil and gas, medical device, pharmaceuticals, and construction industries along with many others. In these industries ABB robots have proven to be an effective automation solution.

So, what exactly can ABB robots be used for? The answer is pretty much any production related application as they have dozens upon dozens of uses. Welding applications including robotic arc welding and spot welding are popular for ABB robot automation, especially in the automotive and metals industries. ABB's 6640 is a powerful spot welder that can be used to weld car frames. Material handling, palletizing, packaging, depalletizing, machine tending, assembly automation, cutting, and deburring are also common uses for ABB robots. Other applications that can be automated with their robots include inspection, painting, sealing, press tending, drilling, polishing, and dispensing. As you can see there are several different uses for ABB robots, and this is only a portion of the list of applications they are capable of automating. The multipurpose capabilities of ABB robots allow a single robot to be able to automate multiple applications. The ABB 4600-20 can be used to automate material handling one day and arc welding the next or it can be used to complete a sequence of tasks along with most of ABB’s other industrial robots. The many uses of ABB robots allow them to be implemented in nearly any manufacturing setting.

Using an ABB robot for automation will result in a more efficient operation. Reducing or eliminating human interaction prevents errors that lead to rework, wasted materials, and longer cycle times. Production costs are lowered through reduced errors and manual labor. While increased productivity, faster cycle times, and higher product quality can expand profit potential. Workers are removed from working with hazardous chemicals/particles, performing heavy lifting, or repetitive movements which improves the overall safety of a production line.

Robots Done Right |

Used Robot Sales |

What are ABB Robots Used For?

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.