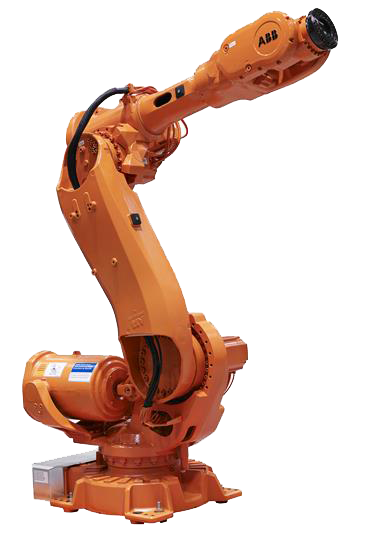

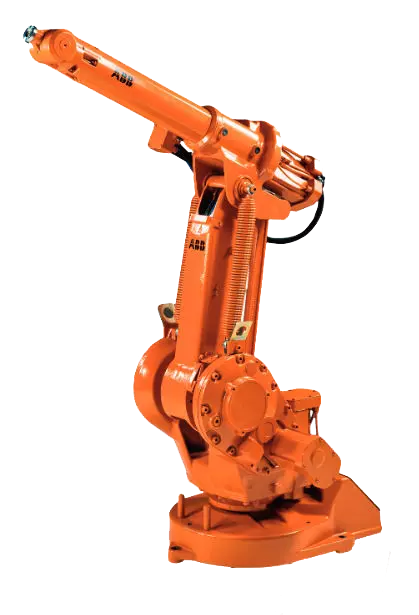

ABB robots are considered to be amongst the best industrial robots in the world. ABB has been producing industrial robots since the 1970s and today they are widely used across a number of industries.

Robot Models

All ABB robots contain “IRB” followed by a three to four digit number in their name. “IRB” simply stands for industrial robot while the first digit in the number that follows generally indicates the size of the robot. Any IRB robot with a number starting with 1 will be ABB’s smaller industrial robot arms, for instance the ABB 1600. The higher the first digit the larger the robot manipulator. The ABB 7600 is one of ABB’s higher payload models. The digits following the first digit indicate the robot model. The higher those are the newer the robot model is. For example, the ABB 4600-40 is the newer version of the ABB 4400-45. There are some exceptions to this, but in general this is the guide followed for ABB robot names.ABB has developed several series of their IRB factory robots. The IRB 100 series features their smallest manufacturing robot arms, the IRB 120 and 140. The ABB IRB 1000 series also features several compact industrial robots with payloads ranging from 4 kg to 10 kg. The IRB 2000 series is comprised of articulated robots with slightly higher payloads and longer reaches than the IRB 1000 robots. The IRB 4000 series features robots with low to medium payload capacities and long reaches. ABB’s IRB 6000, 7000, and 8000 series all feature their larger and higher payload robots. The ABB 7600-500 is one of the heaviest lifters amongst the IRB robots.

All ABB robots are paired with their controller. The newest version, the IRC5 controller, is paired with the latest IRB robots. IRC stands for industrial robot controller.

Applications

Most of ABB’s IRB robotic manipulators are capable of automating multiple types of applications. Some of the most common include arc welding, spot welding, assembly, material handling, material removal, painting, palletizing, and dispensing. The ABB 6640 is commonly used as a handling robot in many industries. ABB’s robots have been installed in numerous factories around the world. They are particularly popular for those in the automotive, electronic, energy, healthcare, and metal industries.Why Automate with an ABB IRB Robot?

ABB IRB robots are some of the most reliable, highest quality, and innovative industrial robots. Automating with an ABB IRB robot will decrease cycle times through their fast operating speeds, elimination of idle time, and consistency. Faster cycle times will increase productivity as more parts can be processed each day.Production costs can be significantly reduced by automating with an ABB robot. Their accuracy and high repeatability prevent errors that cause material waste. Conserving materials reduces costs associated with them. Automating with an ABB robot can also reduce labor costs as no salaries or benefits are required with an assembly robot. Reducing costs while simultaneously increasing productivity provides companies with the opportunity to expand their profit potential. Overall, automating with industrial robots will result in a more efficient production process.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.