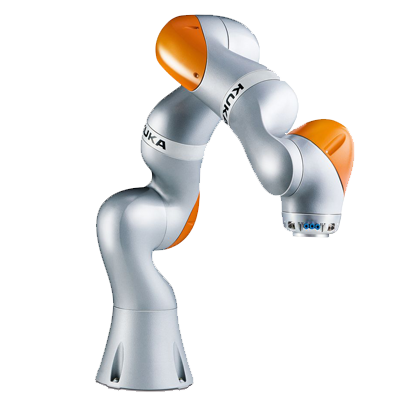

KUKA is one of the industry leaders for robotic automation. Their signature orange robots can be easily recognized and have been automating production lines for decades. Many of KUKA’s KR robots are multipurpose models that are capable of automating a wide range of applications. KUKA’s KR robots can automate assembly, material handling, palletizing, and material removal. Their KR robots can also be used as welding robots.

Arc Welding

Many of KUKA’s light and medium payload robots can be used to automate arc welding applications including MIG, TIG, and plasma welding. The KUKA KR6 is a low payload KUKA robot that is ideal for arc welding. While those needing a little heavier payload could automate with the KUKA KR16. KUKA welding robots feature slim footprints and robotic arms allowing them to access confined spaces and avoid interference. KUKA robots also feature internal cabling which prevents cable snagging and premature wear. Cable life is extended while welding becomes consistent and reliable with the prevention of interference from peripherals.Spot Welding

KUKA also produces robots that are capable of automating spot welding applications. Many of KUKA’s heavier payload robots can be used to automate spot welding. The KUKA KR210 is one of KUKA’s heavy payload robots with spot welding capabilities. Like KUKA’s low and medium payload robots, their heavier payload robots also feature slim footprints. Despite their higher payload, they do not require tons of space. Peripheral interference is avoided with their smaller footprint along with internal cabling. Spot welding applications automated with KUKA robots are extremely reliable.KUKA Weld Cells

KUKA also manufactures several pre-engineered weld cells for arc welding automation. Integrating a KUKA KR30-L16-2 with one of their weld cells can completely optimize your arc welding application. Weld cells in KUKA’s flexibleCUBE line feature compact footprints. KUKA’s other line of weld cells, their flexibleCell systems, are designed for large part welding.Benefits of KUKA Welding Robots

- • Optimal Weld Quality - Automating welding with a KUKA KR60-L45 or another KUKA welding robot will significantly improve weld quality. KUKA robots have incredible path accuracy, high repeatability, and steady robotic arms optimizing the quality of welds. Automating welding eliminates human error which often is the cause of poor quality.

- • Lower Costs - KUKA welding robots can lower production costs. The elimination of expensive welder salaries and benefits reduces labor costs. While the efficiency and accuracy of KUKA robots reduces material and utility costs.

- • Increased Productivity - Cycle times become faster with KUKA welding robots allowing for greater throughput, increasing productivity. KUKA robots can weld twenty-four hours a day with no disruptions. Not only does productivity increase but it also becomes consistent with the reliability of KUKA welding robots.

- • Multipurpose Capabilities - Since KUKA’s KR robots are multipurpose with the ability to automate other applications besides welding, they can be used to automate secondary applications for greater efficiency. The KUKA KR10 R1100 can prepare, weld, and move finished parts reducing the amount of labor or any additional machinery needed.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.