Welding is the process of joining materials, usually metals, together using heat and pressure. Welding was largely performed manually until the 1980s when the automotive industry adopted robots for automated spot welding. Since then robotic welding has continued to grow with about fifty percent of today’s robots being used for automating welding applications. Welding robots provide the skill level of an experienced welder with more efficiency, consistency, and speed. Automating welding processes with industrial robots is becoming even more crucial as seasoned welders retire, widening the welding skills gap in the current workforce.

Robotic welding is the complete automation of a welding application with a mechanical manipulator and tooling that are programmed to handle and weld parts. Robotic welding may also be referred to as automated welding. Industrial robots will complete welds through pre-programmed paths, robotic vision system guidance, or a combination of both methods for more complex applications. The controlled movements of a robotic manipulator ensure precision and accuracy resulting in long-lasting, high-quality welds.

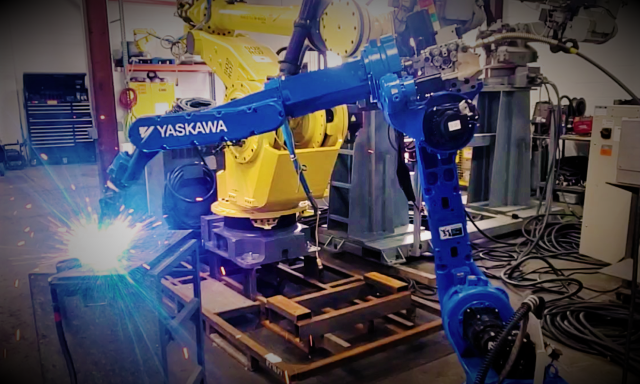

The majority of robots used to automate welding applications are six-axis robots. These articulated robots feature a single arm configuration with the ability to operate from any angle due to their wide range of motion. Six-axis welding robots are able to weld large parts, access difficult angles, or fit into narrow spaces. The FANUC Arcmate 120ic is a top choice of manufacturers looking to automate a welding process. Gantry robots may also be deployed for robotic welding. Their robotic track system makes them ideal for working on large welds, but their range of motion is limited to three axes.

More than just an industrial robot is needed to automate a welding process. Welding robots must be integrated with a robotic welding power supply, welding torch, wire feeder, robotic positioner, and a reamer. All of these components can be contained within a robotic workcell. Robotic workcells provide a safe welding area for robots by shielding floor workers from any welding hazards. Workcells allow robots to operate at their full potential and overallimprove their efficiency.

The typical robotic welding process involves a series of steps that are initiated and monitored by an operator. The operator begins by loading a workpiece from outside the cell onto the first or two workstations. The workpiece will be secured and orientated with the positioner. The operator will use the robot controller to select the desired welding program to run. Once selected, the robot will begin welding inside the workcell while the operator prepares the next workpiece by loading it onto the idle workstation. When welding is complete, the reamer can be programmed to clean the welding torch in between parts. Popular robots used in workcells like these include the ABB 2600 and the FANUC Arc Mate 100ic. Once cleaned the positioner will rotate with the preloaded part, placing it in front of the robot for the next weld cycle. The operator can remove the completed workpiece from the first workstation that is now idle and continue to run through each cycle accordingly.

Robotic welding applications can be broken down into two categories; resistance welding and arc welding. Resistance welding processes include spot welding, which is widely used in automotive manufacturing. The FANUC R2000ib is an example of a robot that can automate spot welding applications. Arc welding processes include MIG, TIG, FCAW, and plasma welding applications. The Motoman MA1400 is designed specifically for automating arc welding.