ABB robots are amongst the most popular industrial robots in the world. ABB’s IRB robots have automated a wide variety of industries including the automotive, electronics, food and beverage, and medical device industries. Their diverse selection of multi-purpose robots allows for just about any application to be automated. The ABB IRB 2600-20 can automate arc welding as well as material handling. While the ABB IRB 6640-235 is a heavy payload robot ideal for palletizing. ABB has those needing a compact robot covered too with the ABB IRB 120.

While ABB manufacturers a wide range of industrial robots that vary by structure, reach, payload, axes, and size, the components that makeup each robot are the same. There are six main components of any ABB industrial robot. They include the manipulator, controller, teach pendant, motors, end-effector, and sensors.

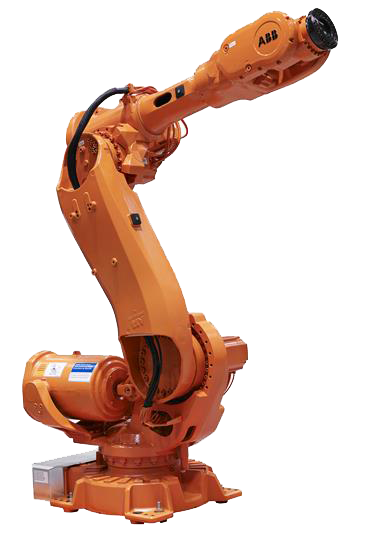

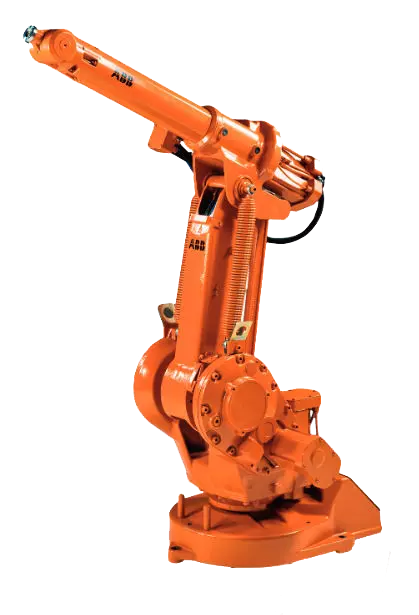

Manipulator

The robotic manipulator is also referred to as the robot arm. It is the component of an ABB robot that executes applications. The majority of ABB robots feature an articulated structure which is designed to resemble a human arm. The manipulator of ABB articulated robots is divided into the shoulder, elbow, and wrist. The shoulder is attached to the base of an ABB robot. The elbow is the jointed part an an ABB robot arm attached to the shoulder. At the end of the arm is the wrist which is responsible for performing the actual application. ABB manipulators consist of a varying number of joints or axes. Most ABB robots have six joints. The ABB IRB 1600 is one of many ABB six-axis robots. There are some ABB robot arms with less axes and some with more than six axes.

Controller

The controller is essentially the “brains” of any ABB robot. ABB controllers feature a computer that is linked to the robotic manipulator. The primary responsibility of the controller is to interpret programming code to allow the robot arm to execute the actions of a given application. Robotic controllers may also be used to store data. ABB has released several different robotic controllers over the years. Currently, the ABB IRC5 controller is used with their robots.

Teach Pendant

The teach pendant is a handheld device used to input instructions in order to program ABB robots. It may be tethered to the controller or have a wireless connection. There are two types of ABB teach pendants, the older legacy pendant and the newer FlexPendant.

Motors

Each joint or axis of an ABB robot arm is fitted with a motor also called the drive. These motors power the joints so they may move into their designated positions allowing the ABB robot to execute an application.

End-Effector

The end-effector is essentially the “hand” of an ABB robot. It attaches to the wrist and interacts directly with workpieces. End-effector types vary by application. For welding automation, the ABB IRB 2600-12 would need a weld torch. While the ABB IRB 4600-40 would be integrated with a gripper for robotic material handling.

Sensors

Sensors are used to provide ABB robots with feedback about their environment. There are a variety of sensors that may be used with ABB robots. Some are used for safety and control purposes. While others are used to enhance robot operation.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.