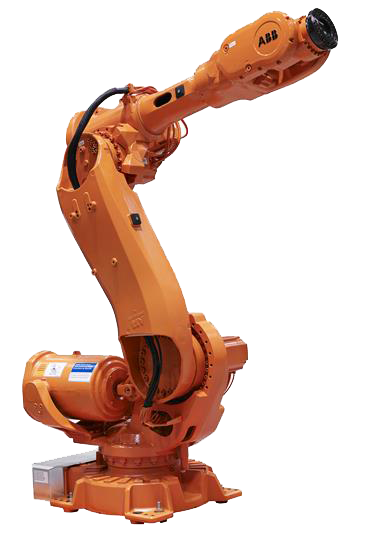

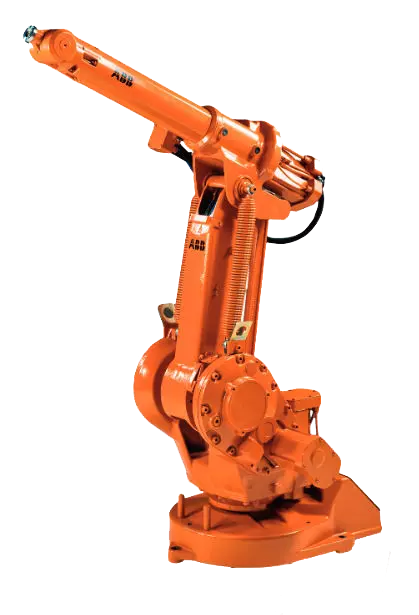

ABB robots are some of the most widely used around the world. ABB manufactures an extensive line of multipurpose industrial robots for automating just about any application. From assembly to material removal to welding, there is likely an ABB robot that can automate your production process. However, in order for successful automation and execution of an application, the robot must be programmed first. Programming ABB robots involves inputting a set of commands through one of the following three methods.

Teach Pendant Programming

Most ABB robots are programmed through the teach pendant method. Teach pendants are the handheld devices that are part of the ABB control system, the IRC5 controller. ABB teach pendants feature a display screen, buttons and switches, as well as an emergency stop button. Newer ABB pendants feature touchscreen technology along with a 3D joystick. ABB’s new pendants are known as their FlexPendants which have replaced their legacy teach pendants. ABB’s FlexPendant is available in either an IP54 or IP65 protected case.Individual commands of an application can be manually entered into the pendant through the keypad or touchscreen. In addition to entering program commands, ABB pendants can be used for running robotic programs, modifying programs, and recalling program history. All of ABB’s industrial robots can be programmed through the teach pendant method. The ABB IRB 4600 can be programmed for automated material handling applications with its pendant. Teach pendant programming allows operators to program ABB robots live, providing them the opportunity to observe movements for the most accurate application execution.

Offline Software

Using offline software is another programming option for ABB robots. ABB has developed their own offline software for their industrial robots called RobotStudio. RobotStudio features both offline programming and offline simulation capabilities. The offline programming feature optimizes the planning and development of robotic applications while offline simulation allows for the testing of applications before going live with them. RobotStudio maximizes efficiency by allowing programs to be fully developed and perfected before involving the actual articulated robot. Creating a new program for the ABB 2400 with RobotStudio can be done through a PC, outside of the production environment. The 2400 can remain in production while programmers develop and optimize the program for its next project.Offline programming is best for more complex applications as it avoids having to key in commands individually through a pendant. This saves vital programming time and allows for six axis robots to remain productive while new programs are designed.

Lead Through Programming

ABB collaborative robots feature another programming method called lead through programming. Lead through programming involves manually guiding a robot’s arm through the waypoints of an application. It is also commonly referred to as walk through programming. Both of ABB’s single and dual arm collaborative robots use the lead through approach as their primary programming method. The simplicity of the lead through method eases the programming process, making ABB’s cobots incredibly user-friendly.Accurate programming is key to the successful automation of a manufacturing process. ABB’s innovative programming technology aids in the development and implementation of robotic automation.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.