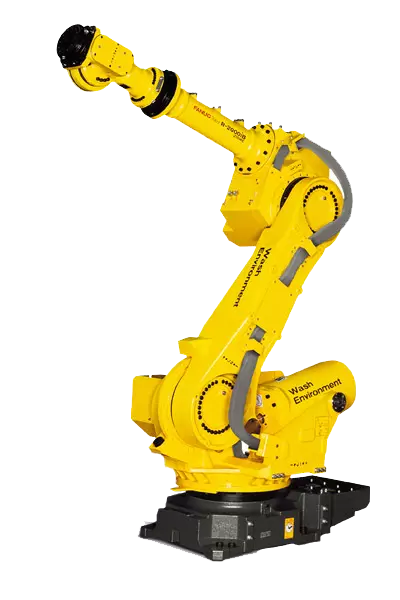

The six-axis robot is the most widely used type of industrial robot, serving a variety of industries from automotive to warehousing. Many manufacturers choose to automate with six-axis robots because they are powerful and reliable machines capable of adapting to most production environments. There are numerous benefits to automating manufacturing lines with these robots, some of the key benefits include:

- 1. Increased Range of Motion - One of the main benefits of six-axis robots is their expanded range of motion. Each axis of an articulated robot provides a degree of freedom or in other words an independent motion. The six axes of these robots allow for access to greater amounts of space, resulting in a larger work envelope than robots with fewer axes. Six-axis robots are capable of reaching every angle in a unit of space, as their robotic arm is designed to be similar to the human arm. An enhanced range of motion makes the FANUC M-10ia ideal for taking over tedious, repetitive, or dangerous manufacturing tasks from human workers.

- 2. Versatility - Another advantage of six-axis robots is their versatility. Six-axis robots give manufacturers flexibility within their production lines. Many of these robots allow for several mounting options including floor, ceiling, and wall. Versatile mounting allows users to make the most of their workspace as those with limited floorspace can mount a FANUC M-710ic/50 overhead. While wall mounting a FANUC R-2000ib/165R will allow for greater workpiece access. Six-axis robots are also capable of performing several different types of robotic applications and work with a variety of workpieces. Some of the most common six-axis applications are arc welding, spot welding, material handling, material removal, and assembly.

- 3. Adaptability - Six-axis robots are extremely adaptable when it comes to workpiece, application, or production changes. Most of these robots are multi-application capable, allowing them to be easily reprogrammed and redeployed should manufacturing needs change. Adaptability is key in many industries prone to sudden or frequent product line changes like the electronic industry. Should a workpiece or process need to be tweaked or completely overhauled, a six-axis robot can adapt to those changes quickly. For those who work with a variety of workpieces, these robots can be integrated with vision systems for on-demand part and location recognition. The FANUC M-20ia can be converted to a Arcmate 120ic with a simple software change and addition of a welding power supply.

- 4. Cost-Effective - Since six-axis robots are both versatile and adaptable, they are a cost-effective investment for many companies that are long-lasting. When there are changes to a manufacturing process, these robots can easily adjust to new requirements. This eliminates costs associated with having to purchase new equipment or having to hire or retrain employees. Well-maintained robots can last for several years to several decades, with most companies being able to recapture their ROI within the first couple of years.

- 5. Automate Complex Tasks - Advancements in six-axis robot technology has made the automation of complex tasks possible. The flexibility, large work envelopes, programming methods, and durability of these robots has widened the scope of robotic applications. These robots can take over complex processes including inspection, mixed bin picking, machining, and welding with more accuracy, precision, and efficiency than humans. Automating complex processes allows companies to expand their manufacturing capabilities.

Robots Done Right is the place to start when it comes to used robots.

Contact us if you are interested in buying or selling your used robot at (440) 724-6568 or email mm@robotsdoneright.com.

Contact us if you are interested in buying or selling your used robot at (440) 724-6568 or email mm@robotsdoneright.com.