Both FANUC and ABB are amongst the top robotic manufacturers in the world. They both produce high-quality, durable, and intelligent industrial robot arms that have been installed across numerous industries. The FANUC R-2000 and ABB IRB 6000 robot series consist of some of the most robust and versatile industrial robots. The robot manipulators in each of these lines are known as true workhorses in manufacturing. Those looking for a high payload, long reach, multipurpose robot will likely be able to find one from either series. Below is a comparison of the FANUC R-2000 and IRB 6000 articulated robots.

FANUC R-2000 Robots

The R-2000 series has been FANUC’s most successful robot series. To date there have been four generations of FANUC R-2000 robots, starting with the FANUC R-2000ia. Following the R-2000iA series, FANUC released the R-2000iB, R-2000iC, and R-2000iD robot lines. Each generation of R-2000 robots has built upon the success of their predecessors. Each line features a standard model with several variations based from it. Variations include extended reach robots, rack mounted robots, wash proof variants, and pedestal mounted options. One of the reasons for the popularity of the FANUC R-2000ib/165F and the other R-2000 robots was FANUC’s ability to design heavy payload robots without being overly bulky. Manufacturers can automate with the FANUC R-2000ib/210F without having to sacrifice significant floorspace, making these heavy payload manufacturing robot arms unique to their class.Payload capacities for the R-2000 robots start at 125 kg and go up to 270 kg. Reaches start at a little over 2,200 mm and can go up to 3,500 mm allowing these six axis robots to easily handle large workpieces and cover bigger work envelopes. Further adding to their large work envelope is their ability to reach fully behind and overhead. Their slim arm and internal cabling allow them to operate in tight spaces without interference. They are one of the few heavy payload robots with the ability to operate in confined work environments. The FANUC R-2000 robots can automate a wide variety of applications. They are especially popular for material handling automation, but can also automate spot welding, material removal, dispensing, palletizing, assembly, and packaging.

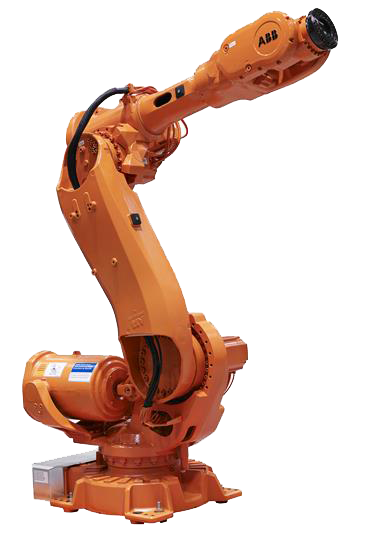

ABB IRB 6000 Robots

Like FANUC’s R-2000 series, the ABB IRB 6000 series features multiple generations of heavy payload, multipurpose factory robots. The series originally started with the IRB 6600 robots, featuring the ABB 6600-175. Since then ABB has developed the IRB 6620, IRB 6640, IRB 6650, and the IRB 6700 generations. There are multiple options in the IRB 6000 robot family including a variety of payload and reach capabilities. The ABB 6640-235 is one of the higher payload robots in the series, while the ABB 6640-130 features an incredibly long reach. Like the R-2000 robots, payloads for the IRB 6000 robots start at 125 kg. However, they go slightly higher to 300 kg. Reaches start out at little longer than the R-2000 robots at 2,550 mm but do not go to as long, maxing out at 3,200 mm. The ABB IRB 6000 robots are also capable of bending fully backwards for greater flexibility within their work envelope. The IRB 6000 robots are floor mounted and do not feature the mounting variations that some of the R-2000 robots do.The ABB IRB 6000 robots automate many of the same applications as the R-2000 handling robots. These include material handling, spot welding, material removal, and dispensing.

Both robot lines feature many similarities as they are designed for heavy payload automation. Choosing between the R-2000 and the IRB 6000 robotic manipulators may come down to payload requirements, reach needs, or simply manufacturer preference.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.