Automating Material Handling Applications with Robots

Robotic material handling has become vital to the overall efficiency of a manufacturing operation. Robots are ideal for material handling as many of these processes involve repetitive, laborious, and ergonomic hazards. Robotic material handling involves integrating an industrial robot with a gripper to allow the robot arm to grab, transfer, or hold parts in place. Material handling robots may interact with conveyors, workstations, or fixed machinery during a given task.

Material handling processes are some of the most common to be automated with industrial robots. Material handling is the largest category of robotic applications as it is comprised of a wide variety of tasks involved with the movement and handling of parts. Robotic assembly, automated machine loading, machine tending, part transfer, automated pick and place, packaging, robotic palletizing, press tending, and injection molding applications all fall under the material handling category. Material handling robots may be programmed, integrated with robotic vision systems, or use a combination of both to accurately carry out these processes. Advancements in gripper technology allow articulated robots to safely handle delicate, small, large, or heavy parts.

Types of Robots for Material Handling

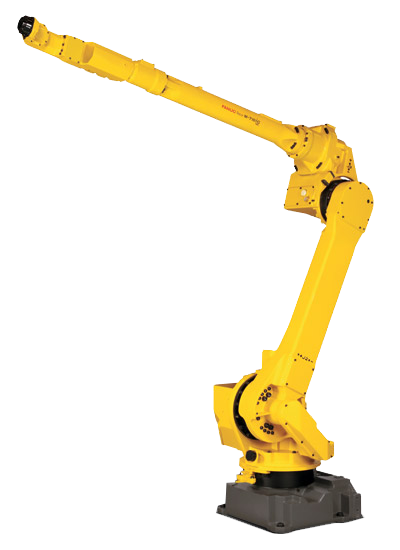

Material handling processes may be automated with articulated, SCARA, delta, or cartesian robot types. The type of robot selected will depend upon the specific application, workpieces, payload capacity, and work envelope requirements.Six-axis articulated robots are the most versatile with a wide range of motion and the ability to automate several types of material handling processes. The FANUC M20ia can perform assembly, packaging, or part transfer tasks. Four-axis articulated robots are best suited for palletizing automation. Their simplified axis configuration provides additional stability and strength for heavy lifting applications. The FANUC M410ib/700 features a reinforcement bar above its arm for the sturdy lifting of pallets.

SCARA robots are mostly used for assembly processes, but can be deployed for light palletizing, machine loading, or packaging. Delta robots are ideal for high-speed pick and place or part transfer tasks. The FANUC M3ia has incredible precision for transferring light parts. Cartesian robots feature a linear track system, which allows them to automate most straight forward part transfer processes. Parts can be transferred across several feet within minutes.

Why Automate with Material Handling Robots?

Automating a material handling process with an industrial robot will lead to an efficient production line. Robots eliminate bottlenecks that are the result of slow part handling. Robots have high levels of uptime as they can operate around the clock with no downtime and at much faster speeds than workers. Their high uptime and fast operating speeds significantly reduce cycle times. More parts can be processed, transferred, or packaged in less time. Production bottlenecks are eliminated as the fast, reliable, and consistent operation of material handling robots keeps production lines on track.As cycle times are improved along with uptimes, productivity rates will increase. Longer operating hours and higher part throughputs both translate to positive productivity gains. Not only will productivity increase, but the repeatability of robots provides consistent and reliable productivity levels. With manual material handling productivity can be unreliable due to inconsistencies in worker performance.