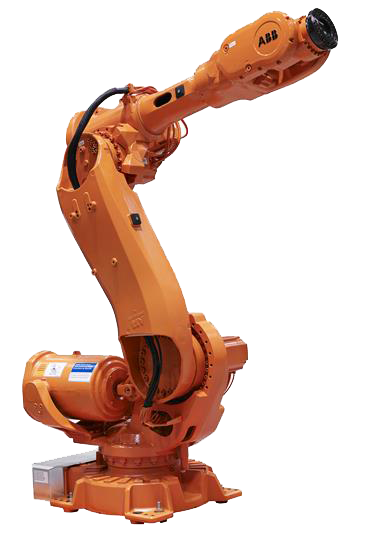

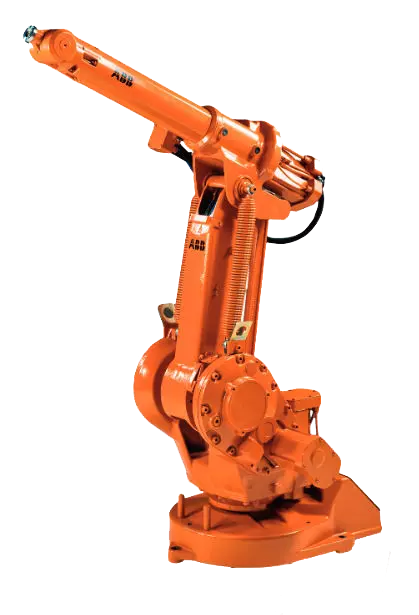

ABB is one of the top robotic manufacturers in the world. They are known for producing innovative, reliable, and intelligent industrial robots, robotic workcells, and software. Popular ABB robots include the 6640 and the IRB 2400. While they originated in Switzerland, ABB has grown its operations to over one hundred countries. Below is an overview of the history of ABB and how they have become one of the leaders in robotic automation.

1970s

During the seventies ABB was known by their former name ASEA. It was in 1974 that they released their first robot, the IRB 6. The IRB 6 was the world’s first robot to be controlled by an electric microcomputer. The following year in 1975, ASEA successfully automated arc welding applications with the IRB 6. After finding success with arc welding, they then turned their attention to designing a spot welding robot. They did just that in 1979 with the IRB 60, which become the first electric spot welder.1980s

After expanding in Europe during the seventies, ASEA entered into the Japanese robot market in 1982. The following year they released their new robot control system, the S2, which could control up to seven axes. In 1986 the IRB 2000 was released. At the time this articulated robot was unique since it was powered by AC motors, becoming the first to do so. In 1988, ASEA partnered with BBC Brown Boveri Ltd and formed ABB Asea Brown Boveri Ltd.1990s

In 1990 ABB broke into the American robot market with the acquisition of Cincinnati Milacron. This allowed ABB to expand into the automotive industry with their spot welding robots. In 1991 the IRB 6000 was developed, becoming the most accurate and fastest industrial robot for spot welding. During 1994, ABB released the successor to their S2 robotic controller, the S4. A few years later in 1998, they developed their incredibly fast FlexPicker delta robot for automated picking and robotic packaging applications. That same year they revolutionized robotic programming with their RobotStudio software that allowed for offline simulation.2000s

During the 2000s ABB really expanded robotic automation with the release of several of their most successful models. In 2001, the IRB 7600 was released and had the highest payload capacity at the time with 500 kg. In 2002 ABB looked to expand the robotic work envelope with their IRB 6600 with its ability to bend fully backwards. In 2004 the IRC5 controller was introduced with the ability to control four ABB robots. 2005 was one of the biggest years for ABB, introducing over fifty new products including the IRB 1600. Rounding out the decade was the release of one of ABB’s most well-known six axis robots, the IRB 120 in 2009.2010-Present

ABB did not slow down during the most recent decade. They launched the IRB 460 in 2010 which was designed specifically for robotic palletizing. In 2013 the IRB 6700 series was developed, making the series the seventh generation of the IRB 6000 robots. In 2015 the world was introduced to ABB’s YuMi collaborative robot. While YuMi is not the first cobot, it is the first to feature a dual arm design.Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.