Comparison of the FANUC Arc Mate 100iB & Arc Mate 100iC

The FANUC Arc Mate series features several welding robots designed specifically for arc welding automation. FANUC arc welding robots feature slender profiles for faster welding speeds and the ability to operate within most workspaces. The 100iB and 100iC robot lines within the Arc Mate series are two of the most popular when it comes to welding automation.

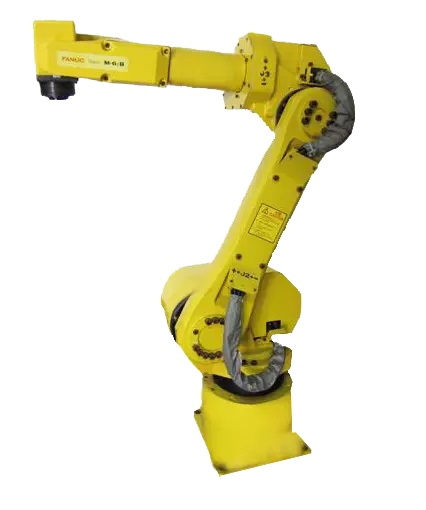

FANUC Arc Mate 100iB

The Arc Mate 100iB is a second generation FANUC arc welding robot as it is the successor to the FANUC Arcmate 100i. It features a payload capacity of 6 kg and a reach of 1,373 mm. The Arc Mate 100iB is designed with a compact footprint and slim arm, allowing for greater part access. There are several model variants based upon the Arc Mate 100iB, including the Arcmate 100ibe which features a greater range of motion. Articulated robots in the Arc Mate 100iB line are paired with FANUC’s RJ3iB controller.The FANUC Arc Mate 100iB can be used to automate arc welding applications including MIG, TIG, and plasma welding. In addition to arc welding, the Arc Mate 100iB can be used for plasma cutting automation. Wire feeders can be mounted directly on top of the robot for a more streamlined configuration. The Arc Mate 100iB integrates well with the Lincoln Powerwave 455M power supply. Air lines, gas lines, and power supply cabling can be routed through the robot manipulator arm, allowing for greater reliability by simplifying the number of external cables. This robot is perfect for automating high-speed welding and is an extremely cost-effective welding automation solution since it is only available as a second-hand robot.

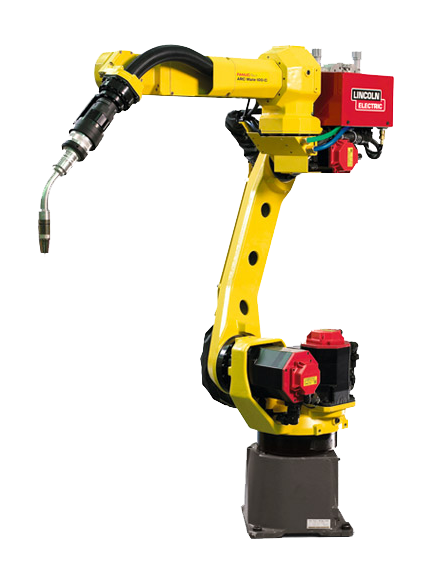

FANUC Arc Mate 100iC

The FANUC Arc Mate 100iC is the third generation of Arc Mate 100i robots. This robot is the successor to the Arc Mate 100iB and features several improvements. The Arc Mate 100iC’s payload capacity was upgraded from 6 kg to 10 kg allowing for the handling of slightly heavier parts and tooling than its predecessor. Its reach was also increased from 1,373 mm to 1,420 mm for a slightly wider work envelope. Another improvement made to the Arc Mate 100iC is the internalization of the wire feeder cable, instead of having it exposed like the Arc Mate 100iB. All cabling related to the torch, air lines, gas lines, and wire feeder are routed inside the hollow robot arm. This prevents cable interference and wear and tear, while also reducing maintenance requirements for greater welding uptime.The Arc Mate 100iC has several more model variants base upon it than its predecessor for greater variety. There are several extended reach variations including the Arcmate 100ic/6L and the 100ic/8L. There is also the short arm Arcmate 100ic/10S for when a more compact work envelope is needed. Like the Arc Mate 100iB, the Arc Mate 100iC can automate MIG, TIG, and plasma arc welding applications with the addition of robotic laser welding. The FANUC Arc Mate 100iC robots also feature an upgraded control system as they can be paired with either the FANUC R-30iA or R-30iB controllers.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling a used robot.