Why Factories are Automating with Industrial Robots

Industrial robots have become the top automation choice of manufacturers on their factory floors. In today’s competitive global market, companies cannot afford to not implement robots. As robotic technology has advanced, the capabilities of robots have also, being able to automate just about any production related application including welding automation, robotic assembly, automated palletizing, material removal, and robotic packaging to name a few. The top reasons why manufacturers are deploying factory robots include:

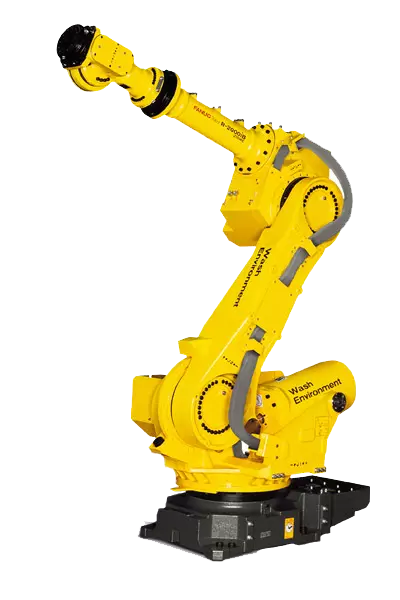

- • Reduce Costs - Reducing costs is always a top priority of manufacturers and can be achieved by automating with industrial robots. Implementing a FANUC M710ic/20L for automated material removal tasks reduces the amount of human interaction needed in the process and thus reducing the chance of costly errors. Robots are accurate and highly repeatable preventing wasted materials. Their fast-operating speeds result in faster cycle times, cutting down on manufacturing time to further save money. Labor costs are reduced as robots do not require a salary or benefits.

- • Improve Quality - Articulated robots are pre-programmed to complete tasks in accordance within the program’s parameters. In addition, they operate with controlled and precise movements. This ensures all products are high-quality and uniform to one another. A FANUC Lr Mate 200ic is able to assemble electronic devices with precision, preventing damage to delicate parts and ensuring all parts are accurately placed. All devices are assembled correctly and do not deviate from product to product. Robots can also be integrated with a robotic vision system for greater accuracy, especially for more complex applications. Robots integrated with vision can even be used to inspect their own work for greater quality control.

- • Increase Productivity - Since robots operate at fast speeds, much faster than human workers, throughput rates can significantly increase allowing for higher productivity. A Motoman MA1400 is able to weld the same number of parts as three welders with its speed and precision. Not only do six axis robots increase productivity with their fast operation, but also with no breaks or delays. Productivity is not only increased but is consistent allowing for more accurate planning and manufacturing quotas.

- • Ensure Worker Safety - Manufacturing jobs are often viewed as dirty, dull, and dangerous. Many manufacturing processes involve the lifting of heavy parts or equipment. Others may involve constant bending, twisting, or reaching. All of these can lead to potential stress injuries. Other jobs may involve working in hazardous conditions such as high dust, extreme temperatures, toxic fumes, or chemicals. The FANUC M710ic/50 is meant to work in tought conditions with its ip rating of 67. Exposure to any of these could lead to adverse health effects in the long term. Implementing industrial robots removes the burden of hazardous or dangerous manufacturing jobs from workers. Workers can instead be deployed to safer, more critical aspects of manufacturing.

- • Close Labor and Skill Gaps - Manufacturing jobs tend to have high turnover as they are not always desirable to workers. Another labor issue for manufacturers is it can be difficult to find skilled labor. Both of these can cause labor and/or skill gaps, making it difficult for companies to fill positions within their factories. Robots solve both of these issues as they are readily available and have the skillset of any seasoned worker. Industrial robots are a long-term manufacturing solution to factory worker shortages.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.