Positive Cash Flow with Industrial Robots

Many manufacturers operate with slim margins leaving little room for error or unexpected costs. However, with rising material costs, along with workers wanting higher salaries, the slim margins of manufacturing are becoming even tighter. Improving cash flow is critical to the success and growth of your company. Positive cash flow means more capital and the freedom to expand manufacturing capabilities. It also means companies are in a better position to absorb additional costs. At at time when costs seem to only be rising many may feel it is impossible to improve their company’s cash flow, but it can be done through robotic automation.

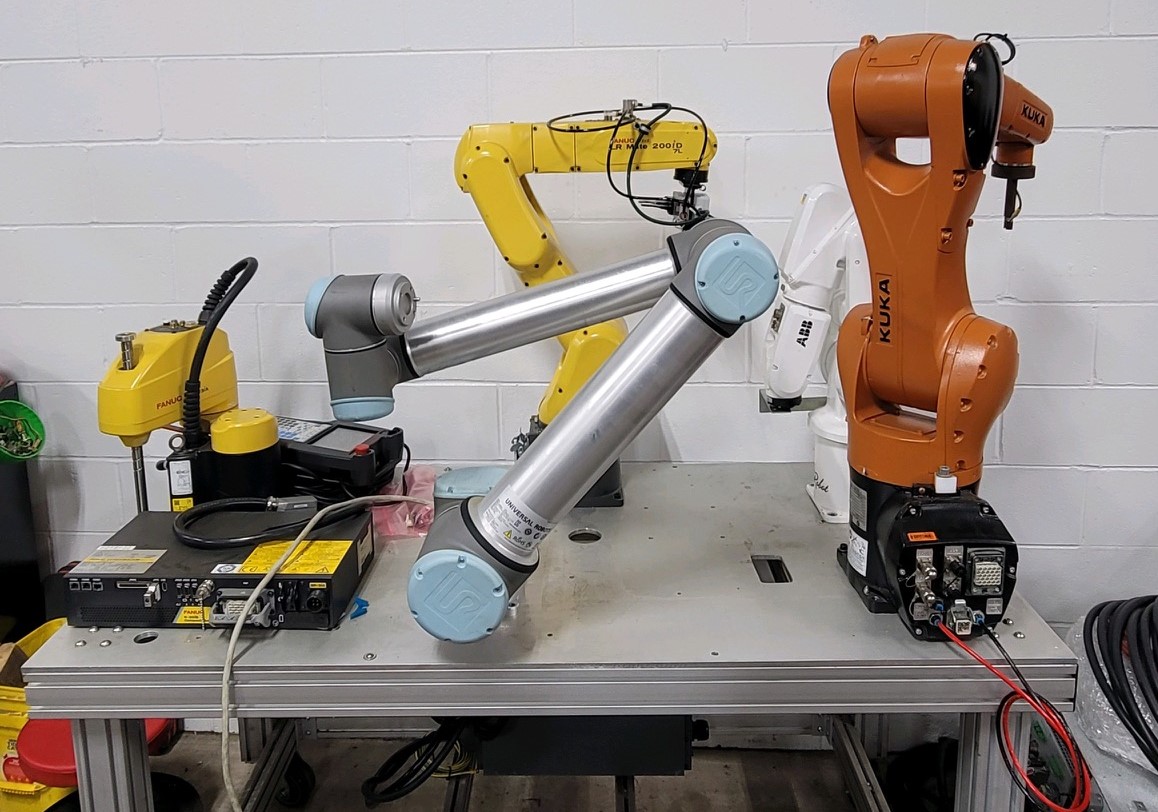

Many often are hesitant to automate with industrial robots due to the initial cost. What they do not realize is that in most cases automating with the FANUC Lr Mate 200ic or another articulated robot will pay for itself and will be a highly cash positive investment in the long run. A company’s cash flow can significantly increase with robotic automation as robots optimize operations eliminating bottlenecks and other negative cash flow factors. With industrial robots costs are reduced, throughput increases, and profit potential becomes higher, improving cash flow for manufacturers.

- • Reduced Labor Costs - Automating with handling robots means companies will be relying less on manual labor for their manufacturing. With fewer workers involved with manufacturing less labor costs will be incurred by companies. This includes salaries and benefits. Factory robots also make manufacturing environments safer by taking over dangerous tasks. Instead of using workers for heavy lifting, the ABB IRB 6640 can be used. This prevents work related accidents and injuries from occurring lowering workers compensation costs for companies as well.

- • Reduced Scraps/Material Waste - Costs for materials have been steadily rising over the past few years, making scraps and material waste some of the biggest obstacles for achieving positive cash flow. Relying on manual labor means higher scrap rates and material waste as humans are naturally error prone. Mistakes lead to scraps and rework causing more materials than those budgeted to be used. Automating with robot manipulators will reduce the amount of material waste incurred by a production. Robots are accurate, eliminating errors and preventing the waste and overuse of materials. Using high repeatability robots like the ABB IRB 1200 means all steps are replicated exactly with each workpiece, preventing errors and material waste. Material costs are reduced with less scrap and become more predictable.

- • Lower Utility Costs - Automating manufacturing with an assembly robot can also lower utility costs for factories. Industrial arms do not require the same light or heating or cooling as humans. Fewer utilities are used with robots, lowering the costs of running a factory.

- • Increased Throughput - Robot arms operate at fast speeds and can run around the clock allowing for greater throughput. More products can be completed in less time for significant productivity gains.

- • Higher Profit Potential - With lower costs and greater throughput, industrial robots allow for a higher profit potential. Fewer costs incurred combined with the ability to manufacture more products in less time will expand profit margins creating a positive cash flow for your company.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling a used robot.