ABB is one of the top industrial robot manufacturers in the world. They have been producing innovative robots for production related tasks since 1974 when they launched the world’s first electrically driven and microprocessor-controlled robot with their IRB 6. Since then they have had a rich history in expanding the boundaries of robot automation.

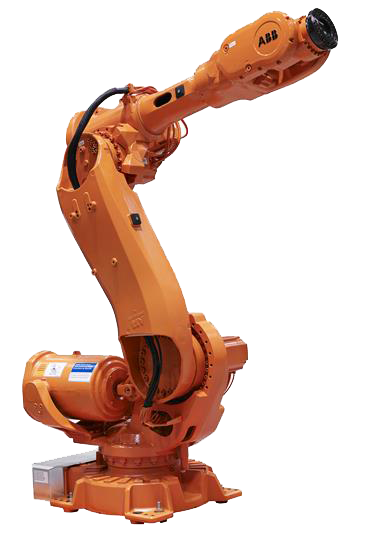

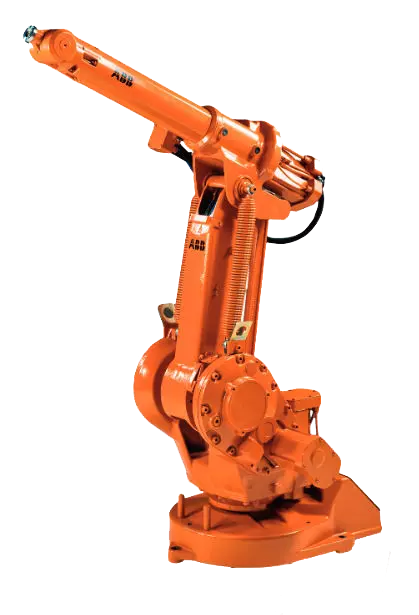

Today, ABB offers an extensive line of articulated, collaborative, SCARA, and delta robots. The ABB 6640 and the ABB 4600 are two of their most successful articulated robot models. ABB robots can automate a wide variety of manufacturing applications including robotic assembly, welding automation, robotic packaging, painting, material handling, and automated material removal. With over 400,000 robots installed across the globe, it seems many manufacturers agree ABB robots are ideal for industrial automation. Automating with an ABB robot is extremely beneficial to manufacturing. Some of the key benefits include:

- • Reduced Costs - While the initial price of purchasing an ABB robot may be expensive, this cost will be offset by the reduced labor and production costs, allowing buyers to realize their ROI relatively quickly. Automating with an ABB robot will dramatically reduce labor costs. A ABB 1200 does not require a salary, benefits, or time off. Other overhead costs such as utilities can also be reduced. ABB six axis robots can operate in dim light or in non-climate-controlled facilities, helping to cut energy bills. In some estimates, an ABB robot can reduce energy expenses by up to 20%. Material costs are also cut since ABB robots eliminate material waste. They are programmed to operate with extreme accuracy, preventing errors that ultimately lead to the use of excess materials. Companies can also save on the purchase of an ABB robot by buying used through a reputable robotic equipment supplier, such as Robots Done Right. In addition, many used ABB robots for sale come integrated with a robotic welder or robotic gripper from their previous application.

- • Improved Quality - Producing consistent, high-quality products can be difficult in manufacturing. Many manufacturing tasks are repetitive and tiresome, making it difficult to produce uniform products. ABB robots eliminate those issues to significantly improve product quality. They operate with accuracy and a high level of repeatability, ensuring each product manufactured meets the same quality standards.

- • Reduced Turnover - High employee turnover is a major issue for manufacturers. Employees experience burnout quickly as industrial jobs are labor-intensive, dangerous, and dirty, making for a less than desirable work environment. Worker shortages can be disruptive to production lines as they can cause slow cycle times, low productivity, and poor product quality. Implementing ABB robots on production lines removes workers from unfulfilling jobs. ABB robots are reliable manufacturing solutions that can be in operation for several years. Time consuming training and recruitment become issues of the past for employers. ABB robots are ready to operate once programmed and can always be redeployed for other applications should manufacturing processes change.

- • Increased Productivity - ABB robots are capable of operating at fast speeds and processing higher throughput rates. For instance, a ABB 1600 can transfer up to 100 parts per minute. Faster operating speeds, high-throughput, and twenty-four-hour operation all translate to increased productivity. Not only do productivity rates increase, but they become consistent and predictable with the reliable operation of ABB robots.