CNC machines are commonly used in manufacturing to automate machining and finishing applications such as milling, drilling, and trimming. CNC machines in the past have been tended to by human operators. However, machining tending can be hazardous, tiring, and repetitive work. What makes CNC machine tending undesirable for humans, makes it an excellent fit for industrial robots. There is a growing trend in manufacturing to automate CNC machine tending with the FANUC M-10ia and other robotic manipulators.

What is Robotic CNC Machine Tending?

Robotic machine tending involves replacing human involvement with CNC machines with industrial robot arms. Factory robots are installed in front of CNC machines either by floor, tabletop, or overhead mounting. They are then used to retrieve parts, transport them to the CNC machine, load parts into the machine, ensure they are correctly positioned, start and operate the CNC machine, remove finished parts, and transfer parts to post-processing.What Types of Industrial Robots can Automate CNC Machining?

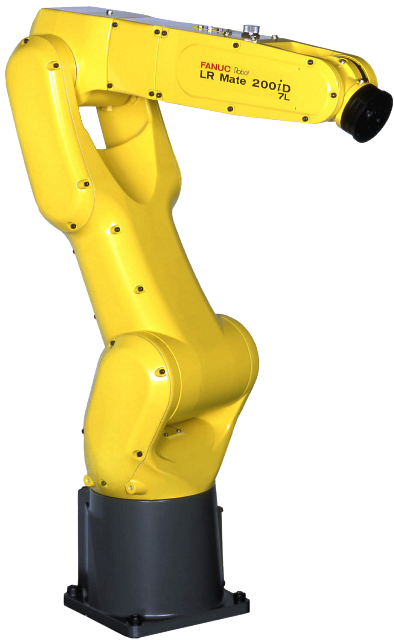

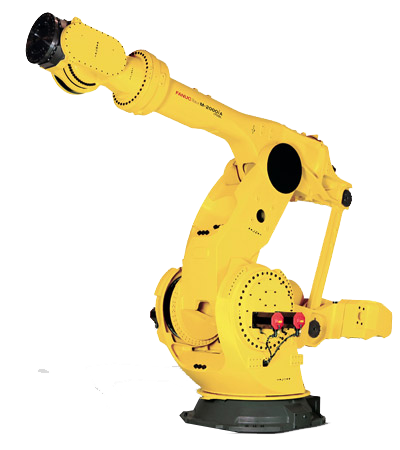

The types of industrial robots that can be used for CNC machine tending include articulated, collaborative, gantry, and SCARA robots. Smaller articulated robots along with SCARA robots are best for when space is limited. They can be tabletop mounted and their compact size allows them to operate in confined spaces without interference. The Yaskawa HP20-6 is a smaller articulated robot that is ideal for CNC machine tending. For CNC processes involving larger or heavier parts a higher payload robot will be needed. Articulated and gantry robots can both be used for heavier workpieces. Gantry robots help save space with their overhead track system. Their track system allows them to tend multiple CNC machines and easily transport parts. Collaborative robots also have the advantage of a smaller footprint, making it easier for them to reach into machinery. Another advantage of the Universal UR10 and other cobots is they require no safety fencing and can be stationed next to workers.Reasons to Automate CNC Machine Tending with Robots

- • Greater Uptime - Automating the tending of CNC machines increases uptime. Unmanned machines and idle time is avoided as manufacturing robot arms can operate around the clock and tend multiple machines. Unexpected downtime with industrial robot arms is extremely rare, allowing operations to run continuously.

- • Reduces Labor/Equipment - Automating CNC machine tending streamlines production floors as less labor and equipment is needed. The ABB 4400/L30 can tend multiple CNC machines as well as automate secondary applications such as material handling. Productions become more efficient while floorspace is freed up.

- • Prevents Incorrect Product Placement - Automating CNC machine tending eliminates human errors. One of the most common human errors is incorrectly placing parts in CNC machines. When this happens workpieces must be scrapped. Robot manipulators are programmed to follow application instructions repeatedly, ensuring correct part placement.

- • Lower Overhead Costs - A robotic machine tending system will cost less to operate than using manual labor to tend CNC machines. Handling robots are more productive and do not require salaries or benefits.

- • Increased Throughput - The fast operation speeds, reliability, and error prevention of industrial robots will significantly increase throughput. With robotic CNC machine tending more parts can be processed in less time than manual methods.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.