Welding automation involves converting a manual welding process into an automatic one using industrial robots. Lack of skilled welders, reduced costs, increased productivity, and better weld quality are all some of the top reasons manufacturers are automating their welding applications. Welding is one of the most common applications for industrial robots as both arc welding and spot welding processes can be successfully automated.

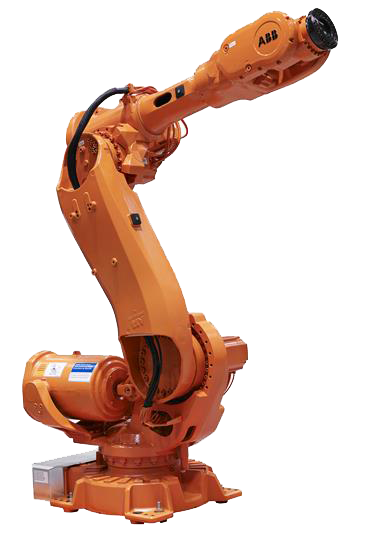

When it comes to selecting a welding robot, it is important to choose a reliable robotic brand. ABB robots are considered to be some of the best in the industry which is why ABB is amongst the top four robotic brands. ABB manufactures several general purpose robots that are capable of automating multiple types of robotic applications, including welding. While ABB does not have a specific industrial robotic arm line solely dedicated to welding, most of their multipurpose robots are capable of optimizing welding tasks.

Arc Welding

Arc welding involves joining metals together through an electric arc. ABB robots can automate several arc welding applications including MIG, TIG, FCAW, and plasma welding. Robotic welders from Fronius and Miller Electric integrate easily with ABB robots for arc welding automation. Six axis robots from the IRB 1000, IRB 2000, and IRB 4000 series can be deployed for automating arc welding.The IRB 1000 series from ABB features a line of robust, low payload robots. The ABB 1410 and ABB 1600 from the series can both be used to optimize arc welding applications. Slender robot manipulators and wrists allow these robots to weld even in confined spaces without interference from peripherals. In addition, internal cabling extends the service life of the articulated robots and ensures reliable welding by preventing cable impediment.

Those looking for slightly higher payloads in an arc welding robot could consider those from ABB’s IRB 2000 and IRB 4000 series. IRB 2000 payload capacities go up to 20 kg while payloads for the IRB 4000 series go up to 60 kg. Both series feature robots with longer reaches for those with arc welding applications requiring a larger work envelope. The ABB 2400L is an extended reach model of the IRB 2000 line.

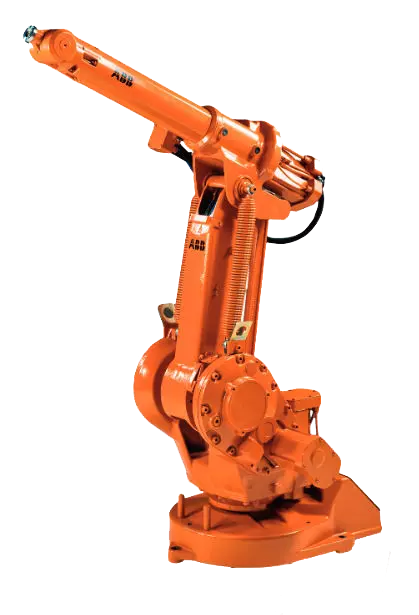

Spot Welding

Spot welding involves joining metals together while they are in a solid form through applying pressure. Unlike arc welding robots which typically feature slender frames and arms, robots used for spot welding tend to be larger. Robotic manipulators used for spot welding also tend to have higher payload capacities since spot welding end-effectors can be quite heavy. ABB’s heavy-duty robots form the IRB 6000 and IRB 7000 series are ideal for automating spot welding processes.The IRB 6000 and IRB 7000 series both contain some of ABB’s highest payload robots. The IRB 6000 series payload goes up to 300 kg. While the payload capacity for the IRB 7000 robots goes up to 500 kg. Factory robots from both lines feature extended reaches that exceed 2500 mm. The ABB 6640-130 and 6640-235 are both ideal for automating spot welding. Their high payload capacities ensure they can handle heavy spot welding equipment, while their long reach allows them greater workpiece access and the ability to weld large parts.