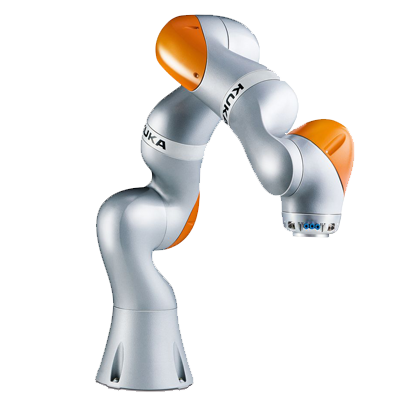

Welding is one of the most common robotic applications. It is estimated that fifty-percent of active industrial robots are used for welding automation. One of the world leaders for industrial robots is KUKA. KUKA is a German based robotic manufacturer that is amongst the top four robotic brands. Over 80,000 of their signature orange robots have been installed in manufacturing facilities around the world, with many of those being used for welding applications.

When it comes to welding automation many often think of Yaskawa Motoman or FANUC robots as both manufacturers have developed specific robot lines dedicated to both robotic arc welding and spot welding. However, many of KUKA’s multipurpose robots are capable of automating arc welding, laser welding, and spot welding processes. The automotive industry is one of the largest users of KUKA robots, especially for spot welding automation.

Many of KUKA’s light and medium payload articulated robots are capable of automating arc welding applications. The KUKA KR 16 is one of their light payload six axis robots that can be used for arc welding processes such as MIG and TIG. The KR 16 is comparable to the FANUC Arcmate 120ic. Those looking for a medium payload welding robot could consider KUKA’s KUKA KR 60-3. KUKA robots are multipurpose with the ability to automate other types of applications outside of welding. In addition to arc welding, the KR60 can also automate assembly, plasma cutting, and drilling applications. The versatility of KUKA welding robots makes them capable of automating an entire metal fabrication process. Even if a KUKA robot is originally purchased for welding but manufacturing processes change, it can still be used for another application such as robotic material handling by simply reprogramming it.

KUKA’s heavier payload robots are capable of utomating spot welding applications. KUKA robots capable of spot welding automation feature payloads over 150 kg making them ideal for handling the heavy end of arm tooling of spot welding. The KUKA KR210 is one of KUKA’s heavy lifting robots that can be used for spot welding. Many of KUKA’s higher payload robots come standard with an IP65 rating but have the option to upgrade to an IP67 rating for operation in harsh work environments.

KUKA also manufacturers their own weld cells for integration with their arc welding robots. KUKA’s weld cells are turnkey robotic systems, meaning they are pre-engineered. Each weld cell features a modular design and comes with a KUKA robot, robotic positioner, welding equipment, and safety package. KUKA’s flexibleCUBE arc Systems are their pre-engineered workcells designed for automated arc welding. The flexibleCUBE cells feature a compact footprint, making them ideal for those with limited floorspace. KUKA’s other line of weld cells is their flexibleCELL arc Systems. These turnkey cells are designed for the welding of large and heavy workpieces. The flexibleCELL workcells are unique since most turnkey workcells cannot accommodate large parts. These KUKA weld cells can handle workloads up to 4,000 kg.

Welding with KUKA robots will improve cycle times, weld quality, and productivity rates. The longer reaches of KUKA robots allows for better part access while their high repeatability ensures all welds are consistent.

Robots Done Right |

Used Robot Sales |

Welding with KUKA Robots

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.