Ways to Upgrade Your Robotic System

When it comes to upgrading a robotic system, users have many options available. Upgrading a robotic system may be necessary at some point to reduce bottlenecks, keep up with competitors, or to allow for process changes. Users may opt to build upon their current system or to purchase brand new. With either option manufacturers will see overall improvements to their operations.

Add Additional Robots

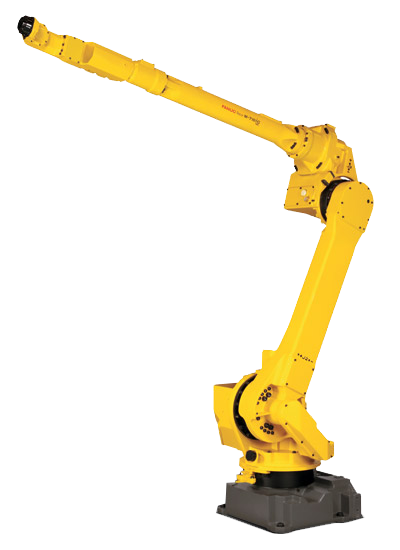

One way to upgrade your current robotic system is to add additional robots. Adding another industrial robot or two to your manufacturing floor will further improve the efficiency of your productions. Productivity will increase significantly as each six axis robot can complete double or triple the workload as a human worker. Cycle times will be dramatically reduced. Costly errors and material waste will also be prevented as more robots eliminate the need for direct human interaction.Determining if there are any bottlenecks in your production process can help you decide which aspects of your production line could be improved through robotic automation. For instance, let’s say you have a FANUC M20ia for assembling parts. However, after analysis you realize cycle times are being dragged out because once parts have been assembled, they are manually transferred to the next workstation. Adding a FANUC M710ic/20L for part transferring can improve cycle times since it can move more parts in less time than workers.

Integrate Robotic Technology

Robotic vision systems and force sensors are two types of robotic technology that can be integrated with robots in order to enhance and upgrade their performance. Robots by themselves are designed to be precise and accurate through programming. Adding vision or robotic force sensors allows for them to be able to adapt to variations through sensory feedback while operating. Adding robotic technology will improve the accuracy of an articulated robot’s operation and make it capable of performing more complex tasks. Robots with vision will be able to identify different types of parts and locations. While force sensors help robots to better control and adjust their EOAT with pressure sensing. Some used FANUC robots for sale come equiped with vision systems and force sensors.Purchase a New Robot

When most think about upgrading their used robotic system, they think about buying a new robot as opposed to adding on to their current one. Many want to take advantage of newer technology and advancements of today’s robots. Fortunately, your current robotic system can help make a new system more affordable. Robots are a smart investment that can still hold value many years later. Trading in or selling your used robot can provide significant capital which can be applied towards a new robot. Selling a used FANUC robot makes buying a new ABB robot more cost-effective. With the high demand for second-hand robots, there has never been a better time to consider upgrading to a new one.Consider a Robotic Workcell

Opting for a robotic workcell is another option for those looking to upgrade and further improve upon their factory automation system. Workcells house all robotic equipment and provide a safe workspace for robot applications. Workcells can accommodate single or dual arm robots and allows them to operate at their full potential. Used Fanuc welding robots integrate nicely with different positioning equipment to optimize an arc welding application. They streamline production lines and are beneficial for automated welding, robotic assembly, and robotic material removal applications. Depending upon a user’s budget and application requirements, workcells may either be pre-engineered or custom designed.Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.