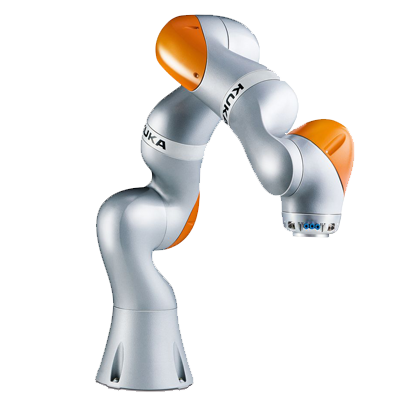

Programming is critical to the operation of industrial robots. It involves creating a set of commands for a specific application and relaying those instructions in code for a robot to understand. Robotic programming in the past has been complex and one of the main contributing factors to robotic automation hesitancy. Fortunately, robot programming has become more intuitive over the years. KUKA has been one of the most innovative robot manufacturers, especially in regard to robot programming. Below is a look at the three programming methods for KUKA robots.

Teach Pendant

The main programming method for KUKA robots is the teach pendant. Teach pendants are handheld devices that are a part of an industrial robot’s control system. These devices are used to input application commands, troubleshoot, and recall operation/robot history. There are two types of KUKA teach pendants, the legacy teach pendant and the smartPAD pendant. KUKA’s legacy pendant features a traditional pendant design with a display screen and keypad. The legacy pendant is compatible with older KUKA robot models, those using KRC1, KRC2, and KRC3 controls. The KUKA KR6 can be programmed with a KUKA legacy pendant since it uses the KRC2 controller.The smartPAD is KUKA’s latest teach pendant version and is compatible with KUKA KRC4 robots. The smartPAD features a lightweight design and touchscreen display. The smartPAD allows for user-friendly programming, permitting users of any programming experience level to be able to operate it. The smartPAD is compatible with KUKA’s newer robots since is uses KRC4 controls, those include the KUKA KR10 R1100.

Offline Software

Offline software is still relatively new to robotic programming, but many manufacturers have developed offline programs including KUKA. KUKA offline software allows for the programming of their robots outside of a production environment. A PC is utilized to develop and optimize programs without involving the actual articulated robot. Once the application program has been finalized it can be uploaded to a KUKA robot to go live. KUKA offers three offline software programs that combine programming and simulation. Users can create programs and then test them through a simulation that is a replica of their current work environment. KUKA offline software is an efficient and cost-effective programming method, especially for complex applications. Programming downtime is avoided as robots can remain operating while new applications are developed.Demonstration

KUKA robots can also be programmed by demonstration, also known as lead through programming. KUKA traditional industrial robots and collaborative robots can be programmed through this method. KUKA’s smartPAD teach pendant features hand guidance technology. Each smartPAD comes with a 6D mouse that can be used by an operator to manually guide the robot manipulator arm through the waypoints of an application. The motions are translated into commands on the teach pendant and can be adjusted or added to as necessary.Demonstration is the main programming method for KUKA cobots. Users can manually guide the KUKA iiwa 14 R820 by hand through the steps of an application. Demonstration allows for quick, intuitive programming of KUKA robots for a more user-friendly experience.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.