One of the keys to the success of automating a production process with industrial robots is thorough planning and programming. The development of robotic offline software allows for more reliable and cost-effective implementation of robotic automation. Many offline software options combine programming and simulation allowing users to develop and fully optimize modifications or implement completely new robotic applications.

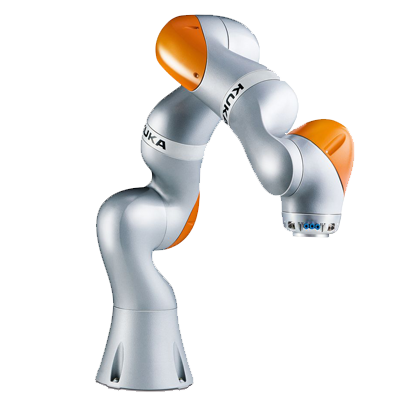

Most of the top robotic manufacturers have developed their own offline software programs. KUKA is one of those manufacturers, offering three different offline software options for their industrial robots. KUKA’s offline software programs combine both programming and simulation in a virtual 3D representation of the work environment. Users are able to develop new programs, modify pre-existing applications, test workcell or production floor layouts, and conduct feasibility analyses. Offline software allows for the thorough and reliable planning of an automated assembly application prior to going live with the KUKA KR210. Users can develop a proof of concept to ensure a production process can be reliably automated by the KR210. Errors and potential hazards can be flagged and worked out prior to launching the application program. This ensures the most accurate articulated robot operation while saving time, making KUKA offline software extremely cost-effective. KUKA’s three options of offline software include:

- • KUKA.OfficeLite - KUKA.OfficeLite is a virtual replica of the system software used for KUKA’s KRC4 controller. KUKA.OfficeLite is compatible with any KUKA robot using the KRC4 control system. This includes both the ________ and __________. This offline software is ideal for developing offline application programs. Since it is a replica of the KRC4 system, users are able to develop realistic applications that correspond directly to the robot’s operation. After developing an application through KUKA.OfficeLite, the program can be directly transferred to the KUKA controller for immediate operation. KUKA.OfficeLite is not only ideal for application development, but also for robotic training.

- • KUKA.Sim - KUKA.Sim is KUKA’s offline software that combines both programming and simulation. Through 2D or 3D simulation users can create and test robotic applications with a computer, outside of the production environment. In addition to program development, KUKA.Sim allows for cycle time analysis, collision detection, reachability checks, and workcell layout analysis. Through KUKA.Sim users can determine if a robot application and robotic system layout are feasible before implementation. This allows for the most thorough planning and optimization of a KUKA robotic system. With KUKA.Sim users can verify if the KR-10 R1100 is best for their automated material handling process while optimizing cell layouts and cycle times.

- • KUKA.SafeOperation - Ensuring the safety of your work environment is important when implementing robotic automation. Robots and workers need to co-exist safely on production floors. KUKA.SafeOperation is an offline software tool that allows users to plan robot workspaces and worker protected spaces to ensure factory safety. With KUKA.SafeOperation users define the robot workspace, protected space, and monitor these spaces and the workcell. By defining and monitoring these spaces, KUKA.SafeOperation enables users to reduce space requirements of the KUKA robotic system. Users are able to develop compact work areas for their robot without compromising worker safety.