When to Implement a Robotic Vision System

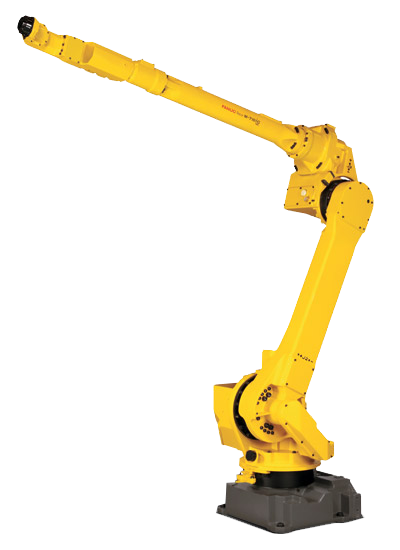

Robotic vision systems are the most widely deployed type of robotic technology with many manufacturers choosing to enhance the capabilities of their industrial robots with them. The components of robotic vision systems work together to provide human-like sight feedback to robots, allowing them to operate more intelligently. A FANUC Lr Mate 200id advances from being able to only perform simple, repetitive processes to more complex and sophisticated ones through vision guidance.

Vision systems are commonly utilized for assembly, pick and place, palletizing, arc welding, and material removal applications among many others. Just about every robotic application can benefit from the addition of a vision system. However, these systems do add an additional cost and may not be necessary for everyone looking to automate with industrial robots. Having an understanding of when to implement a robotic vision system will help you determine if one makes sense for your application and will be a good investment.

Robotic vision systems should be implemented for applications that involve a high mix of several different part types. Vision guided robots are able to identify and distinguish varying part types without having to be reprogrammed for each. This saves significantly on production time and keeps operations fluent for positive productivity levels. Vision makes robots capable of making adjustments on-demand while operating, allowing them to take on more challenging and complex tasks. A FANUC M-10ia integrated with vision can quickly identify specific parts needed for assembly placed within a mixture of part types. This enhances automation capabilities and takes robotic pick and place applications to the next level. A robot without vision would not be able to identify a specific part type from a mixture. The parts would all need to be alike and located in the same location for retrieval, limiting manufacturing flexibility.

Vision systems should also be implemented for robots that will be operating in close proximity to workers. Vision systems not only provide extra guidance for robots to enhance their capabilities, but also make them safer. Vision systems allow robots to be able to better detect when objects or people are close to their workspace to avoid collisions and improve worker safety. Integrating a vision system with a Motoman MH24 alerts it when a worker is too close so it can either slow its movement or stop operation altogether. Vision systems are especially vital to the safe operation of collaborative robots since these robots are designed to work directly alongside humans without any barriers.

Additional use cases for robotic vision systems involve those requiring monitoring for quality control measures. For some manufacturers staffing workers to monitor production quality may not be feasible due to the twenty-four-hour operation of robots or because of worker shortages. However, robots integrated with vision can be deployed for inspection processes. Inspection robots provide enhanced accuracy and efficiency. Minor flaws can be detected by a FANUC Lr Mate 200ic through vision guidance that would have gone unnoticed if inspected by a worker.

While robotic vision systems are not required for all applications or production processes, they can greatly improve robot operations boosting accuracy, productivity, and quality.