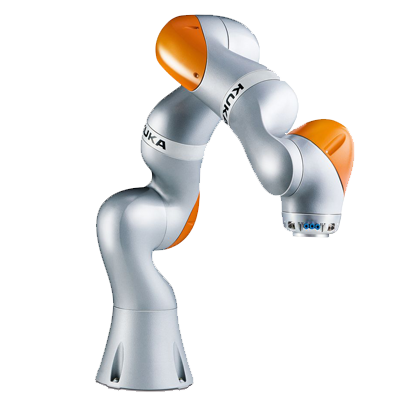

KUKA is amongst the top manufacturers for robotic automation. Their signature orange industrial robots are well known to many manufacturers in the automotive, electronics, and healthcare industries along with many others. Their innovative and intelligent robotic manipulators are capable of automating a wide variety of applications. KUKA robotic automation optimizes production processes through faster cycle times, higher productivity, better product quality, and lower costs.

Those looking to automate with a KUKA robot for the first time or those unfamiliar with articulated robots may be curious to learn what components go into a KUKA robotic system. In general, a KUKA robot will consist of the robotic manipulator, the controller, and the teach pendant. The robot manipulator is another term used to describe the six axis robot. It is divided by two parts; the robotic wrist and the robot arm/body. The wrist is responsible for controlling the movements of the EOAT. In general, the EOAT is not included with a KUKA robot. However, there are used KUKA robotic packages for sale that may include all equipment for a given application. In cases of buying a KUKA KR16 or another used KUKA robot the EOAT may be sold with it as part of a robotic package. Since the EOAT varies by application type, it is usually purchased in addition to the KUKA robot. The second part of the robotic manipulator, the arm/body, controls the movement of workpieces within the work envelope of the KUKA KR10 R1100 and other KUKA robots. The structure of the robotic manipulator will vary by specific type. KUKA manufactures articulated, SCARA, delta, and collaborative robot types.

The controller and teach pendant are always included with new KUKA robots and usually included when buying used KUKA robots. Sometimes used KUKA robots are sold without the controller or pendant, but sellers will state this upfront. In cases of a robot manipulator only sale, a replacement controller or teach pendant can be typically sourced through a used robotic equipment reseller such as Robots Done Right. The type of KUKA controller that comes with your industrial robot arm will vary and depend upon the type of robot and whether it is new or used. New KUKA robots will likely feature their KRC4 or KRC5 controllers. While used KUKA robots will typically be paired with either the KRC2 or KUKA KRC4 controllers. The KUKA KR6 is a used KUKA robot featuring the KRC2 controller. While the KUKA KR6 R900 is a used KUKA robot with KRC4 controls. Some KUKA robots may feature the Sunrise cabinet, which is KUKA’s compact robotic controller.

KUKA robots with KRC4 or KRC5 controls will come with the smartPAD teach pendant. The KUKA smartPAD pendant features a touchscreen display for entering programming and operating the robots. Older KUKA controllers and robots will likely include KUKA’s legacy style pendant. The legacy pendant features a traditional teach pendant design with a keypad and display screen.

The manipulator, controller, and teach pendant are the items that are included with the KUKA robot itself. A KUKA robotic system will likely need other components that will vary by the type of application being automated. These can consist of application specific software, end-effectors, safety devices, and welding equipment.

Robots Done Right |

Used Robot Sales |

What is Included with a KUKA Robotic System?

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.