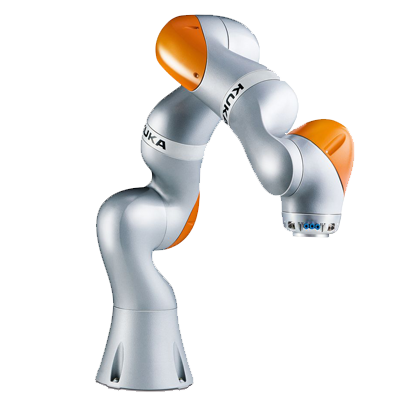

KUKA is one of the top robotic manufacturers in the world. KUKA industrial robots are easily recognizable with their signature orange exteriors and have been deployed for automating numerous industries. KUKA has a deep history in robotic automation which dates back to the 1970s. Over the years they have developed some of the most innovative, durable, and high quality robots including the KUKA KR10-R900 and the KR 60-3. One of the reasons KUKA robots have remained in the top of the industry is due to their continued advancements of robotic technology including their own robotic vision system.

KUKA.VisionTech is KUKA’s in-house vision system for their industrial robots. Vision systems are one of the most popular technology options for articulated robots. KUKA has taken away the guess work for trying to find a compatible vision system for their robots by developing their own. KUKA.VisionTech integrates easily with KUKA robots that use the KRC4 controller. KUKA’s KR6-R900 and KR 30-3 are two of their six axis robots that are compatible with KUKA.VisionTech since they both use KRC4 controls.

Adding KUKA.VisionTech enhances the accuracy and intelligence of a robot for an overall better performance. The vision system uses a high-quality camera to provide visual feedback to the robot about the workpieces and surrounding environment. The robot uses this feedback to process changes while in operation, avoiding the need to reprogram. KUKA.VisionTech allows robots to handle unpredictable and randomized applications through sensory feedback with sight. With a vision system, KUKA robots are able to automate more complex tasks and are more flexible in their operation. For instance, with vision the KUKA lbr iiwa-14-R820 is able to recognize objects when they are grouped in a randomized order.

Some of the features of KUKA.VisionTech include a camera that is capable of 2D part recognition. The camera is enclosed in an IP67 rated case, allowing the vision system to be integrated with robots operating in hazardous conditions. The durability of the vision system ensures proper operation even in high dust, humidity, or wet work environments. Other features include object, code, and character recognition capabilities. These features allow KUKA robots to detect different part types, inspect objects, and recognize product codes. KUKA robots with vision can be setup for automatic quality control checks, safeguarding product quality.

KUKA.VisionTech technology can improve and enhance robot performance for a number of robotic applications. Robotic pick and place applications are the most common, as these benefit greatly from a robot’s ability to recognize parts and locations. The KUKA Kr16 through vision can select specific parts from a high mix of parts within the same bin. KUKA.VisionTech can also improve packaging, palletizing, depalletizing, material handling, assembly, and machine loading/unloading applications. Applications in which a continuous path needs to be followed can also benefit from a KUKA robot with vision. KUKA welding robots integrated with vision are able to weld with greater precision, find specific weld joints, and automatically adjust to weld path changes. Vision also allows KUKA robots to automate inspection tasks of either their own work or the work of others. KUKA industrial robots with vision are able to catch defects that may be missed by humans, ensuring consistent, higher quality products.

Robots Done Right |

Used Robot Sales |

KUKA Vision Systems

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.