KUKA is one of the top robotic manufacturers in the world. There have been over 80,000 of their signature orange robots installed across the numerous industries. The automotive industry has been the largest user of KUKA robots for automating spot welding and robotic material handling processes. KUKA robots have also been implemented in non-industrial sectors including the entertainment industry. Throughout the years KUKA has developed innovative and intelligent robots from the KR 5 R650 to the KR60-3.

KUKA has been in business for over 120 years. The company was founded in 1898 by Johann Josef Keller and Jakob Knappich in Germany to manufacture lighting. The name KUKA came about from a telegram abbreviation for “Keller und Knappich Augsburg.” In the early 1900s, KUKA expanded into developing welding automation with the invention of oxy-fuel welding. They would continue innovating welding technology through the 1960s.

It was not until 1973 that KUKA broke into the robotic industry. That year KUKA changed the industrial robot world with their Famulus robot model. The KUKA Famulus was unique because it was the first robot to feature six electric motor axes. They continued their innovations in the robotics industry in 1985 when they developed the Z-shaped robotic arm. The arm design allowed for six degrees of freedom for complete flexibility of robotic movements. In 1989 they developed brushless motor drives for a new generation of articulated robots, simplifying maintenance. KUKA also expanded into North America during the 1980s and by the end of the decade they were the top welding automation manufacturer in Europe.

After several years of developing and improving industrial robots, KUKA took on the challenge of improving robotic control systems. In 1996 they did just that with the release of the first PC-based robot controller. This made it possible for users to move robots in real time through a Windows interface. This made automating with industrial robots much easier.

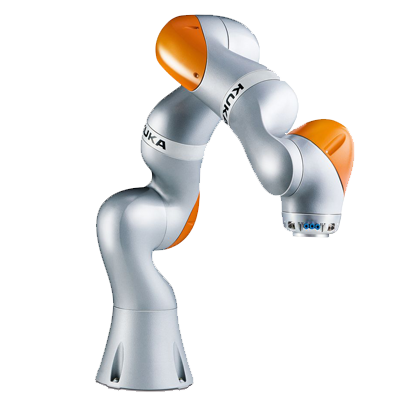

In 2004, KUKA added another world first with the development of their LBR 3 robot. The KUKA LBR 3 wasn’t like any other industrial robot because it allowed for direct human interaction without safety barriers. It was the world’s first collaborative robot, also known as a cobot. A few years later KUKA was recognized by the Guinness Book of World Records with the invention of their KR 1000 TITAN robot in 2007. At the time the KR 1000 TITAN was the world’s strongest six-axis robot with a payload capacity of 1000 kg. Until the release of the FANUC M-2000ia, this heavy payload robot was the largest available.

In 2010, KUKA released its KR QUANTEC line, which quickly become a bestselling robot series due to their unique payload capacities of 90 kg to 300 kg. A few years later in 2012, the KUKA KR Agilus line was released that featured small robot models such as the KR 10 R1100. The compactness and versatility of the Agilus robots has made them quite popular for low payload applications. In 2013, KUKA built upon the success of its original cobot with the release of their LBR iiwa series featuring the lbr iiwa 14 R820.

KUKA has a rich history of robotic innovations which is why they have remained an industry leader.

Robots Done Right |

Used Robot Sales |

KUKA Robotics History

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.