How 3D Vision Systems are Advancing Robotics

The industrial robot industry has been experiencing rapid growth with more manufacturers choosing to automate with robots each year. This growth can be attributed to the expansion of robotic applications through advancements made in robot technology. Vision systems are one of the technologies responsible for the improvement of industrial robots.

Robots integrated with vision systems are often referred to as vision guided robots (VGR). When robotic vision systems first became available, they consisted of 2D cameras. 2D systems provided guidance to robots, but they had their limitations since they could not provide imagery information beyond a single plane. The limitations of 2D robotic vision led to the development 3D VGR systems and the expansion of robotic applications.

3D vision systems allow robots to view objects in six degrees of freedom, x, y, and z planes along with yaw pitch, and roll motions. This is feasible through the integration of a 3D camera with a Time-of-Flight (ToF) camera. This technology has advanced the scope of robots to be capable of more complex tasks that were once thought only possible through human workers.

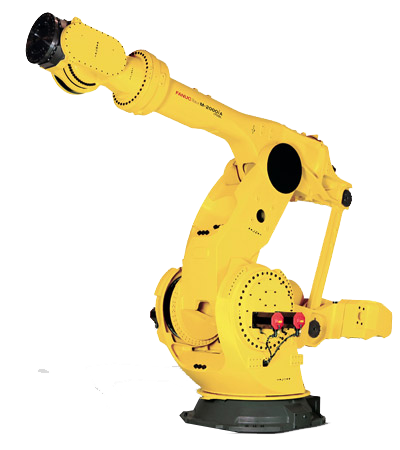

Before the introduction of 3D vision systems, robot applications needed to have a high level of repeatability for parts. However, 3D VGR eliminates this requirement for robotic applications, allowing for greater versatility than before. Robots guided by 3D vision can handle object variations including location, size, color, shape, etc. A FANUC M-10ia integrated with 3D vision can detect the orientation of parts that need handling, even if the parts are located in different bins. The M-10ia can also detect the correct part mixed in a bin with other part types with its 3D vision. The robot then picks the part and can place it on a conveyor for assembly, even in low light settings, a limitation of 2D vision systems. This allows for increased manufacturing flexibility as parts no longer need to be the same. Robots are able to adjust to object changes dynamically instead of needing reprogramming or deferring to human workers.

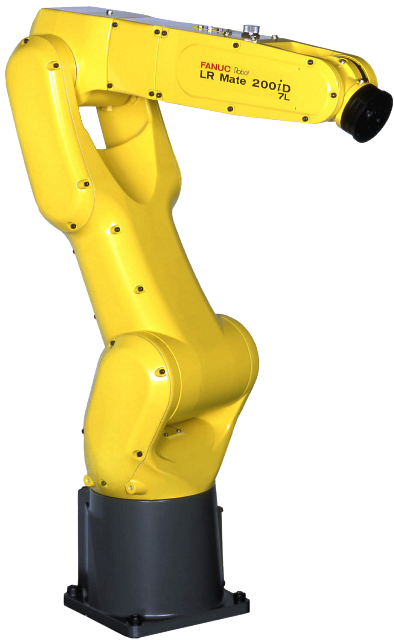

Another advancement from 3D vision systems is the improved accuracy of assembly applications. A FANUC LR Mate 200ic can pinpoint the precise location of a small screw needed to be inserted into the outer casing of a smart phone through accurate robot arm guidance provided by the 3D vision system. 3D vision also provides robots with the capability to inspect their work for quality control. 3D vision provides all angles necessary for thorough product inspections. 3D VGR can also catch defects that are too small for the human eye to see, helping to significantly improve product quality.

Other applications being improved by 3D robotic vision include arc welding, cutting, and palletizing. The integration of a FANUC R-2000ib/165F with 3D vision gives it the capability to handle boxes of varying dimensions during palletizing. The vision system provides the FANUC R-2000ib with feedback about the sizes of the boxes for accurate handling and stacking on pallets.

3D VGR systems are revolutionizing the scope of robotic applications. As 3D systems continue to advance, they are becoming more cost-effective and easier to integrate. Robots are now more efficient, versatile, and productive with 3D vision.

.