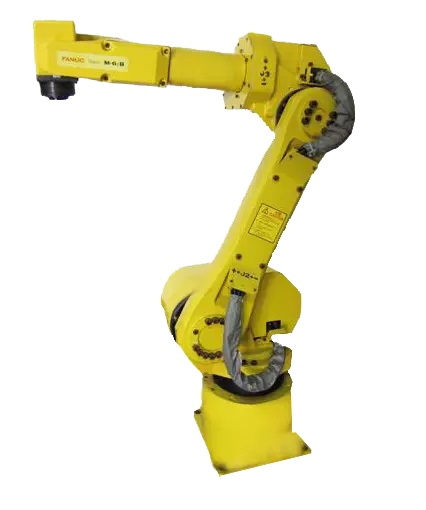

FANUC M-6iB vs KUKA KR6

The FANUC M-6iB and the KUKA KR6 are two common industrial robots used to automate low payload applications. Both FANUC and KUKA are amongst the top robotic manufacturers in the world with many of their industrial robot arms being used to automate numerous industries. When industrial robots from top robot brands like FANUC and KUKA have similar properties it can make selecting one seem somewhat confusing. While the FANUC M-6iB and KUKA KR6 have some similarities, their differences can mean one may be a better fit than the other for your application. Below is a guide on how these two robot manipulators compare to one another.

Robot Features

The FANUC M-6iB is a six axis robot with a payload of 6 kg. The M-6iB has a standard reach of 1,373 mm and a repeatability of +/- 0.08 mm. It also features a relatively light robot mass of 135 kg.The KUKA KR6 shares the same axis configuration and payload as the FANUC M-6iB. However, it has a longer reach of 1,611 mm allowing it to operate within a slightly larger work envelope. The KUKA KR6 has a repeatability of +/- 0.1 mm, making it slightly less precise than the M-6iB. Its robotic manipulator mass is also considerably heavier than the FANUC M-6iB at 235 kg.

Applications

The FANUC M-6iB is a multipurpose robot capable of automating a variety of applications. It is most commonly used to automate material handling applications as well as pick and place and robotic machine tending processes. The FANUC M-6iB can even be used to automate arc welding applications as it is essentially the same articulated robot as the FANUC Arc Mate 100iB.The KUKA KR6 is also considered to be a multipurpose robot with its various application capabilities. Like the M-6iB, it is commonly used as a low payload handling robot. It also shares the ability for welding automation. Other applications that can be automated with the KUKA KR6 include assembly, cutting, packaging, palletizing, and machine loading.

Installation Options

Both the FANUC M-6iB and KUKA KR6 allow for multiple installation options. These industrial robot arms can be floor, ceiling, or wall mounted. This gives users of both of these robot manipulators greater flexibility when it comes to installing them along production lines. Those with limited floorspace have the option to install these manufacturing robot arms above or at an angle. The lighter mass of the FANUC M-6iB does provide it with an advantage as it will be easier to install overhead or relocate the robot.Robot Variations

The FANUC M-6iB is available in several variations including a short arm, cleanroom, and higher speed options. These variants of the M-6iB allow users to take advantages of the main features of the factory robot but with more tailored options for their application needs such as a compact workspace or a cleanroom environment. The FANUC M-6iB is available with the RJ3iB, RJ3iC, and R-30iA controllers.Unlike the FANUC M-6iB, the KUKA KR6 does not feature additional variations. Older KUKA KR6 robots are paired with the KRC2 controller, while newer KR6 industrial robotic arms are paired with the KRC4 controller.

Click below for more information on this models:

Robots Done Right is the place to start when it comes to used robots. Contact Matt at 440-724-6568 or by email mm@robotsdoneright.com if you are interested in buying or selling your used robot.