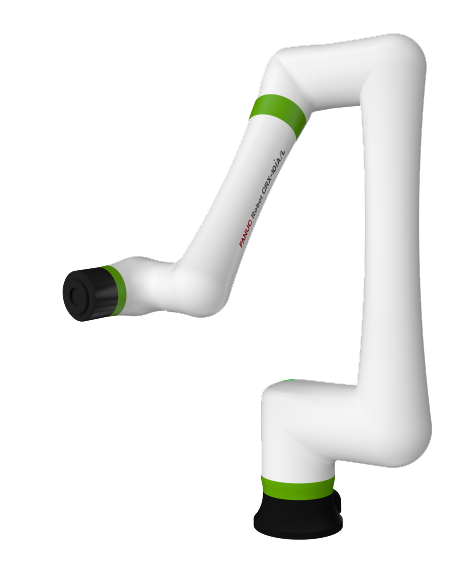

Machine tending is a common process in CNC shops. While CNC machines are used to automate machining and finishing processes, they still require some intervention in order to load and unload parts. In the past, the tending of CNC machines has been done manually. However, manual CNC machine tending is repetitive and hazardous. In addition, labor shortages are making it difficult for manufacturers to fill less than desirable positions such as the tending of CNC machines. This has led to the automation of machine tending with industrial robots. Up until recently, this process has mainly been automated by the FANUC M-10ia and other traditional robotic manipulators. Now there is another type of robot automating CNC machine tending, the collaborative robot.

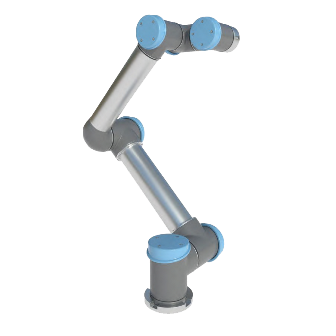

Collaborative robots have only been around for a short period of time, but they have quickly become one of the most common types of robots. They have proven especially beneficial for repetitive material handling applications like machine tending. The Universal UR10 is ideal for loading and unloading parts from CNC machines.

Why Automate CNC Machine Tending with Cobots?

One of the top reasons to automate CNC machine tending with cobots is their small footprint. Collaborative robots are compact with a light mass. They also do not require traditional safeguarding equipment that the Yaskawa Motoman MH12 and other articulated robots do, further reducing their footprint. Cobots can easily be installed amongst CNC machines, operating in confined spaces. Some may even be installed directly into the machine, the FANUC CR-7ia is one such cobot.Another reason for automating CNC machine tending with cobots is their quick changeovers. Collaborative robots can be programmed within minutes through hand guidance. This allows them to quickly be reassigned tasks and fill in where needed. Their light mass means they can easily be moved around CNC shops, tending to which ever machines are operating. Cobots are ideal for automating operations with high product turnover or a high mix of parts.

Collaborative robots also tend to be more affordable than other types of robot manipulators. The elimination of extra safety equipment makes collaborative automation cost-effective especially for smaller CNC shops. A lower up front cost also means a faster ROI. Purchasing a used Universal UR5 will further reduce the cost of automating CNC machine tending.

Automating CNC machine tending with cobots will optimize operations. Bottlenecks will be eliminated as machine tending is no longer dependent on the speed of manual labor, which tends to be inconsistent. Cobots can operate continuously and at faster rates than humans. Productivity increases while idle machine times are reduced.

Another reason why CNC shops are automating with collaborative robots is because cobots can safely operate around and interact with humans. With other industrial robot arms greater safety measures are needed as factory robots can be dangerous to humans. However, cobots are designed with sensors, force limitation, and speed monitoring making them capable of operating around workers without increasing their safety risk. Cobots can be a welcome addition to your CNC shop, automating repetitive processes and assisting employees for an overall better work environment.