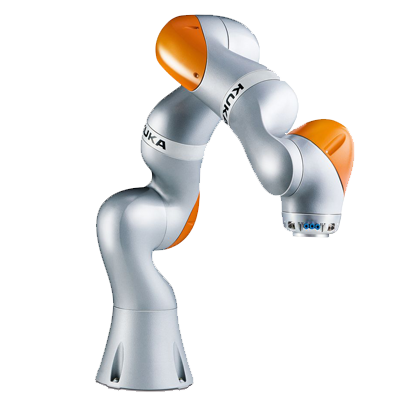

KUKA is one of the most well-known robotic manufacturers in the world. They have been responsible for numerous robotic innovations including designing the world’s first electro-mechanic 6-axis robot, the first PC based controller, and the first collaborative robot. From the KUKA KR16 to the LBR-iiwa7 R800, KUKA offers a wide range of industrial robots. Choosing a used KUKA robot for manufacturing automation brings a number of benefits for complete optimization of any production process.

One of the biggest benefits of KUKA industrial robots is their cost-effectiveness. KUKA industrial robots are some of the most affordable in the industry. Articulated robots are one of the few investments that will pay for itself over time. Automating with the KUKA Kr10 R1100 will save you money in the long run by reducing labor, material, and even utility costs. As costs are significantly decreased, productivity and manufacturing efficiency are increased, allowing for profit growth. Manufacturers can quickly capture their ROI, making automating with KUKA robots extremely cost-effective. Purchasing a KUKA robot can be made even more affordable with investing in a used KUKA robot. The cost of a used KUKA robot can be 50% less than a new one, making an even faster ROI possible.

Another benefit of KUKA robots is they provide manufacturers with flexible automation. KUKA robots can operate in a variety of fields including the automotive, electronics, metal, and even the entertainment industry. They can operate with a variety of parts through programming or integration with vision. They can also perform numerous types of robotic applications including automated welding, robotic assembly, painting, packaging automation, and robotic palletizing. One KUKA Kr60-3 can be used to complete multiple steps of a manufacturing process, streamlining operations. Their flexibility is invaluable to manufacturing as they can easily adapt to production changes. All it takes is reprogramming and they will be an expert at their new task immediately. There is no production downtime or increased costs associated with retraining employees. Unlike fixed machinery that can only perform one specific application, KUKA robots can be repurposed to adapt to any future manufacturing modifications.

Users of KUKA robots will also enjoy the advantage of their low maintenance requirements. Regular robotic preventative maintenance is crucial for ensuring robots are operating at their top level and to prevent unexpected breakdowns. All robots have recommended maintenance intervals, similar to cars. KUKA robots have one of the longest maintenance intervals amongst robotic brands, with a system run time of 20,000 hours in between routine tune-ups. This provides an incredible amount of uninterrupted operation time. Longer periods of time in between scheduled maintenance allow for more productivity as less downtime is required to maintain the optimal operation of KUKA robots.

One more benefit of automating with KUKA robots is their incredible accuracy. KUKA robots operate with extreme accuracy with every cycle run. Their high accuracy significantly improves product quality. Errors such as paint overspray, uneven surface finishes, and inaccurate assemblies are eliminated with KUKA robots. Their pinpoint precision ensures materials are not wasted, parts are not damaged, and that each workpiece is uniform for high-quality manufacturing.

Robots Done Right is the place to start when it comes to used robots. Contact us if you are interested in buying or selling your used robot.